This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

This article has been viewed 1,400,638 times.

Learn more...

Screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. The first time you see a callout can be a little confusing, but it’s pretty straightforward once you know what the numbers are meant to stand for. The callout basically corresponds to the length and diameter of the screw’s shaft. There are a couple of different labeling systems throughout the world, so keep in mind which one the callout uses. By understanding callouts, you will be better able to pick the right screws for any project.

Steps

Using Callouts for American Screws

-

1Look for a label with the callout printed on it. It is usually not printed on the screw. You have to look for a label on the packaging or on the shelf where you bought the screw. The callout looks like a long line of numbers and symbols, like #4-40 UNC-3A x .5.[1]

- If you are unable to identify the screw through its callout, you may need to measure it yourself. The easiest way to measure a screw is with a thread gauge or screw checker.

-

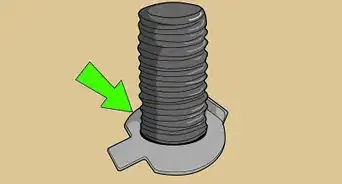

2Use the first number to figure out the diameter of the threads. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. In the Unified Thread Standard (UTS) system, manufacturers list the diameter size as a number between 0 and 10, with 0 being the smallest and 10 being the largest. Screws larger than a #10 have a diameter listed directly in inches.[2]

- For example, on a #4-40 UNC-3A x .5 screw, #4 represents the diameter. It has a diameter of 0.112 in (0.28 cm).

- The diameter is sometimes listed as a fraction, such as ¼. It has a diameter of 1⁄4 in (0.64 cm).

- To help decipher the number ratings, look up a conversion chart online.

Advertisement -

3Read the second number to find the number of threads per inch. It can also be called the thread pitch. Metal screws tend to have more threads per inch than wood screws, for instance. Coarse screws also have a larger pitch measurement than fine screws.[3]

- A #4-40 UNC-3A x .5 screw has 40 threads per inch. A ¼-20 screw, by comparison, only has 20 threads.

-

4Use the abbreviation to determine the thread standard if it is listed. The thread standard gives you additional information about the number of threads on the screw's shaft. Manufacturers often list it for the sake of accuracy. The most common one is UNC, which means Unified National Coarse. You may also see Unified National Fine (UNF) and some other standards.[4]

- If you see a callout like #4-40 UNC-3A x .5, the UNC tells you that you have a coarse screw.

- UNC or coarse screws are the most common type and used for general purposes. UNF or fine screws have a smaller pitch, making them stronger and more resistant to damage, such as from vibration.

- You may also see a J, like UNJC or UNJF. These screws are bigger and even stronger than regular screws.

-

5Look for a number from 1 to 3 indicating the tolerance class. If the callout includes the tolerance class, it is telling you what kind of nuts or holes the screw is meant to fit into. A size 1 screw has the most space between its threads, so it fits more loosely when it is used. Size 3 is the tightest fit and used for accuracy. Size 2 screws are the ones you will end up working within most cases.[5]

- Note that the tolerance class is also divided into A and B. For instance, you might see 2A and 2B screws, which are slightly different sizes. A represents the external threads on the screw shaft and B represents the internal ones.

- For instance, a callout of #4-40 UNC-3A x .5 corresponds to a 3A screw. This kind of screw is used for tight fits.

- If you plan on securing a screw with a nut, find one with a matching tolerance class.

-

6Note if the screw has an LH for left-handed. Left-handed screws are unusual because they are threaded in reverse. When you turn a left-handed screw clockwise, it loosens instead of tightens. Left-handed screws are often used when right-handed screws would normally come loose, such as on bicycle pedals and other rotating parts.[6]

- For example, #4-40 UNC-3A x .5 is not a left-handed screw. A left-handed version would be labeled like #4-40 UNC-3A-LH x .5.

- Most screws you use at home will be right-handed screws. However, if you find a screw marked with LH, you will know to turn it in the opposite direction!

-

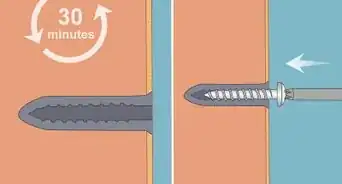

7Use the final number to determine the screw’s length. The number indicating the length typically comes after an “x.” It also tends to be a small number similar to the diameter measurement, making it easier to spot when you’re looking at a long callout. Most screws are measured from the end of the shaft to the bottom of the head. However, note that flathead screws, designed to sit flush when placed, are measured from the top of the head.[7]

- For unified threads, the length is given in inches. A #4-40 UNC-3A x .5 screw is 0.5 in (1.3 cm) long.

- The length can be written as a fraction or a decimal, so you will also see screws labeled like #4-40 UNC-3A x ½.

Reading a Metric Screw Callout

-

1Find the screw thread callout number. It won’t be on the screw. Look to the packaging or store label for more information. If you’re using a blueprint or another source of information, the label may also be there. The callout will look like a string of several numbers.[8]

- For example, a metric screw callout looks something like M12 x 1.75 x 85.

- If you aren’t able to find the callout, measure the screw yourself. If you have a nut or another fastener with a known size, you could also try securing the screw in it.

-

2Note that the letter “M” means you have a metric screw. Screws with the metric labeling always have the letter M. Looking for the metric designation is important if you think you might have other types of screws mixed in. The metric labeling system has a slightly different callout than something like the UTS system.

- If you use different labeling systems at the same time, you may end up with screws that look similar but are a slightly different size. Always figure out the labeling system the callout uses.

-

3Look at the first number to find the screw’s diameter. The diameter number will be listed next to the M. It corresponds to the width of the threads on the screw’s shaft. In the metric system, the diameter is always measured in millimeters.[9]

- For instance, on a M12 x 1.75 x 85 callout, M12 is the diameter. It means the external threads are 12 mm (0.47 in) wide.

-

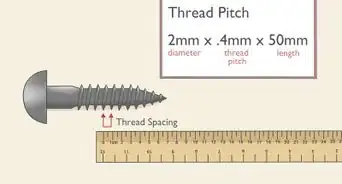

4Read the next number to figure out the screw’s pitch. The pitch represents the distance in millimeters between the grooves on the screw’s shaft. It will follow an “x” after the diameter number. Specifying the pitch is important for distinguishing between coarse and fine screws. Coarse screws have a larger pitch than similarly-sized fine screws.[10]

- A M12 x 1.75 x 85 screw, for instance, has threads every 1.75 mm (0.069 in). The second number, 1.75, indicates the pitch.

- The metric labeling system doesn’t label coarse or fine screws, so you have to pay attention to the pitch. Coarse screws are used in general applications, but fine screws are more resistant to damage.

- If you don’t see a pitch size listed, assume that you have a coarse screw. Sometimes the pitch isn’t listed because coarse screws are used much more frequently than fine screws.

-

5Use the last number to determine the length of the screw. The length will follow an “x.” It is easy to tell apart from the pitch number because it is larger. Also, if you only see 1 number after the diameter listing, then you know you’re looking at the length of a coarse screw. The length is always measured in millimeters.[11]

- For example, a callout of M12 x 1.75 x 85 corresponds to an 85 mm (3.3 in) screw shaft.

- Keep in mind that most screws are measured from the end of the shaft to the bottom of the head. The exception is flathead screws, which are measured from the top of the head.

Community Q&A

-

QuestionAre the male and female referring to the threads on the adapter? Or to the threads on the two pipes that can be connected with the adapter?

Community AnswerMale and female refers to where the actual thread is. A Male thread is on the outside (think of the thread on a bolt or screw). A female is threaded on the inside, like you would find on the inside of a nut or the socket for a light bulb.

Community AnswerMale and female refers to where the actual thread is. A Male thread is on the outside (think of the thread on a bolt or screw). A female is threaded on the inside, like you would find on the inside of a nut or the socket for a light bulb. -

QuestionWhen referring to a screw thread, what does the "20" in 1/4" *20 mean?

Community AnswerThe 20 is the number of threads per inch.

Community AnswerThe 20 is the number of threads per inch. -

QuestionCan I sell online in bulk, since it is a rate per kg?

Community AnswerYes, no problem. Just make sure you also give the weights in imperial, to save confusion.

Community AnswerYes, no problem. Just make sure you also give the weights in imperial, to save confusion.

Warnings

- The system the callout uses is very important since similar screws can be different sizes. Tapered pipe threads, for instance, follow different sizing guidelines.⧼thumbs_response⧽

- Metric callouts look somewhat similar to U.S.-standard ones and are often easy to confuse. Context helps avoid errors, such as knowing that the screw came from a non-American car.⧼thumbs_response⧽

References

- ↑ http://www2.mae.ufl.edu/designlab/Online%20Resources_files/fastener_handout.pdf

- ↑ https://www.experimentalaircraft.info/articles/aircraft-building-9.php

- ↑ http://homepages.cae.wisc.edu/~me231/online_notes/dimensoning/fastener_handout.pdf

- ↑ https://www.yamawa.com/Portals/0/resource/en/tips/pdf/tips-010.pdf

- ↑ http://portal.ku.edu.tr/~cbasdogan/Courses/MDesign/course_notes/fasteners.pdf

- ↑ http://homepages.cae.wisc.edu/~me231/online_notes/dimensoning/fastener_handout.pdf

- ↑ http://portal.ku.edu.tr/~cbasdogan/Courses/MDesign/course_notes/fasteners.pdf

- ↑ http://www2.mae.ufl.edu/designlab/Online%20Resources_files/fastener_handout.pdf

- ↑ https://www.dpti.sa.gov.au/__data/assets/pdf_file/0011/134120/DPTI_Structures_Group_-_Drafting_Guidelines.pdf