X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 12 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 87,028 times.

Learn more...

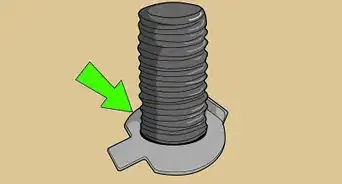

Lock wiring is the securing together of two or more parts with a wire which will be installed in a way that any tendency for a part to loosen will be counteracted by an additional tightening of the wire. Lock wire or safety wire is applied in situations where extreme mechanical reliability is needed. Due to a lot of vibration and other forces acting on the aircraft, aircraft use a lot of lock wire to secure fasteners from falling apart.

Steps

-

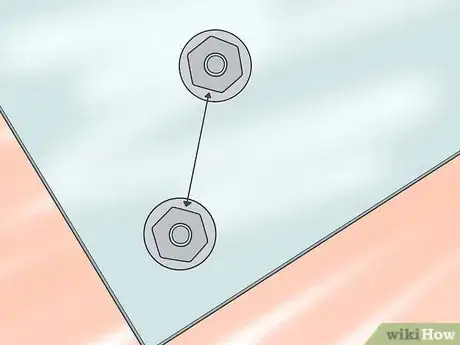

1Decide the length. The length of the piece of wire to be used is determined by the distance between the bolts that need to be lock wired.[1]

-

2Cut the length. The wire should be cut to a length that is a little bit longer than twice that distance between the bolts.[2]Advertisement

-

3Take the safety wire, thread one end of the safety wire through one of the holes and pull it back, and thread the other end through another hole in the same bolt and bring them together.

-

4Put the two ends of the wire equal in length and form a loop through the bolt head.[3]

-

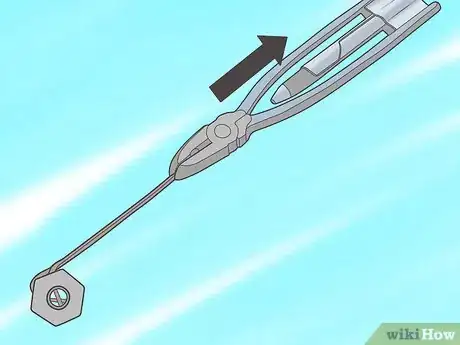

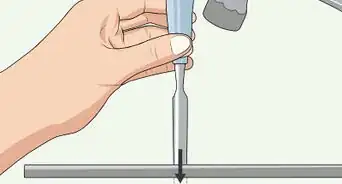

5Grab the wire a short distance before the loose ends with using the safety wire pliers tool. Pull together until the two ends are firm and tied around the first drilled-head bolt.

-

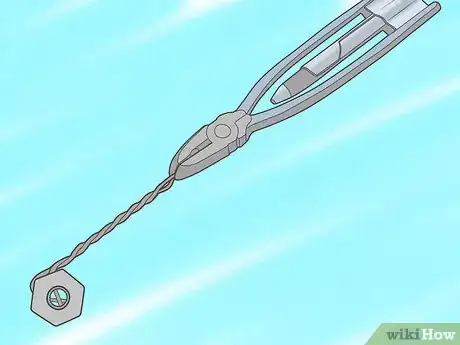

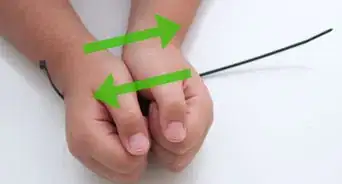

6Using safety wire pliers grab the 2 wires where they reach the halfway of the second bolt and twist them 2-9 times depending on the diameter of the wire used, the thicker the wire is the less turns needed.[4]

-

7Release the wire from the tool, with the two loose ends remaining adjacent to each other.[5]

-

8Insert one of those ends through one of the holes on the bolt, and pulled through the other hole, then insert the other end through the hole and bring the two ends together.

-

9Put the two ends of the wire equal in length and form a loop through the bolt head.

-

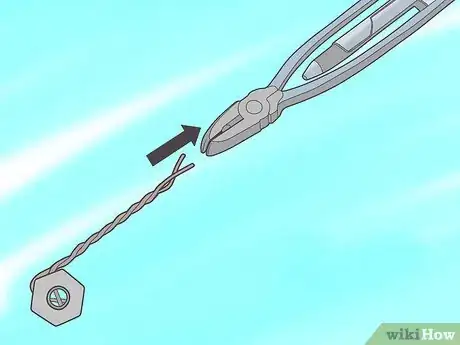

10Repeat the twisting process on the two loose ends and fold them towards the bolt in a way so the wire won't lose itself.

-

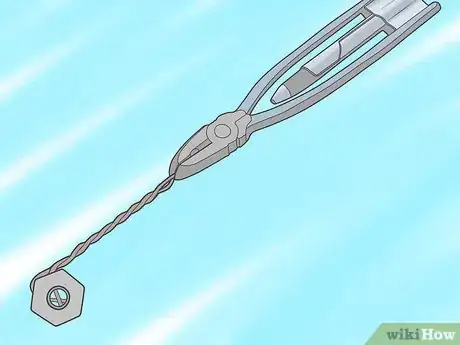

11When done, cut and twist the loose end with a pair of diagonal cutters or the safety wire cutters to prevent cutting fingers.[6]

Advertisement

Things You'll Need

- Use the preferred sizes 0.020, 0.025, 0.032 of wire depending on the size of the hole in bolt. The smaller sizes are used for smaller holes. The wire diameter used is 0.020, or 0.025. The larger sizes are used where stronger wire is required. Wire diameter of .032 is the most commonly used and will be used in the video.

- Safety wire pliers

- A pair of diagonal cutters

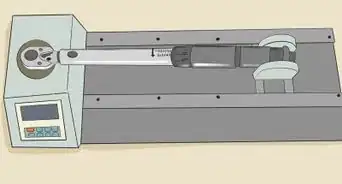

- A lock wiring board

References

- ↑ https://www.youtube.com/watch?v=7Xck44xYeaE

- ↑ https://www.youtube.com/watch?v=FJ7wHpER9R4

- ↑ https://www.oldbritts.com/52_130202.html

- ↑ https://www.youtube.com/watch?v=7Xck44xYeaE

- ↑ https://www.youtube.com/watch?v=7Xck44xYeaE

- ↑ https://www.youtube.com/watch?v=7Xck44xYeaE

- Byron Gliding, Byron Bay Gliding Club, www.byrongliding.com/lockwire.htm - Research source.

About This Article

Advertisement