This article was co-authored by Ricardo Mitchell. Ricardo Mitchell is the CEO of CN Coterie, a fully licensed and insured Lead EPA (Environmental Protection Agency) Certified construction company located in Manhattan, New York. CN Coterie specializes in full home renovation, electrical, plumbing, carpentry, cabinetry, furniture restoration, OATH/ECB (Office of Administrative Trials and Hearings/Environmental Control Board) violations removal, and DOB (Department of Buildings) violations removal. Ricardo has over 10 years of electrical and construction experience and his partners have over 30 years of relevant experience.

There are 12 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 97,773 times.

Whether you’re working on an electrical project or selling wire for scrap, you’ll need to strip insulation off of the actual metal conductors. Wire stripping tools are easy to use, and come in a variety of designs that fit wires of any size and type. You could also use a utility knife to cut and remove insulation, but it takes a practiced hand. Since magnet wires have an enamel coating that’s too thin for a stripper or knife, your best option is an abrasive surface, such as fine-grit sandpaper.

Steps

Using a Wire Stripping Tool

-

1Get a wire stripping tool labelled for your type of wire. Wire strippers look like pliers with a number of notches set in the jaws. These notches vary in size to fit different wire types and gauges. There are a range of designs available for a variety of wires, such as electrical cords, coaxial cables, or thin communication wires.[1]

- You can find wire strippers that fit your needs online or at your nearby home improvement or electrical store.

-

2Find the notch that matches your wire’s gauge. If you know your wire’s gauge, find the corresponding notch in the jaws of your wire strippers.[2] For example, if you have a 16-gauge wire, find the notch marked 16.[3]

- If you don’t know the gauge, or if your tool isn’t labelled, place the wire in each notch to find a match. The wire should fit snugly into the notch.

Advertisement -

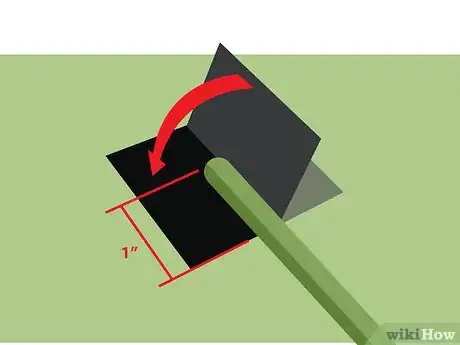

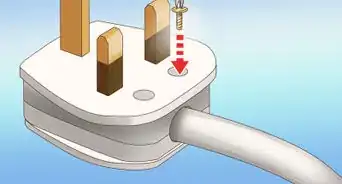

3Place the tip of the wire in the appropriate notch. Once you’ve found the right notch, place the wire in it, then gently close the tool’s jaws. Line it up so the jaws are about an inch (two to three centimeters) from the end of the wire.[4]

- If you’re using the wire for an electrical project, you’ll only want to strip the insulation off of the tip. If you’re stripping wire for scrap, it's more efficient to just slice down the length of the wire with a utility blade instead of pulling off a little bit at a time with wire stripping pliers.

-

4Squeeze the stripping tool’s handles gently. Try to use just enough pressure to cut through the insulation. You don’t want to squeeze too hard, or you might damage the wire beneath the insulation. This would make it unsuitable for an electrical project.[5]

- If you’re using the notch with the right gauge, you should be able to cut through the insulation without doing any damage.

-

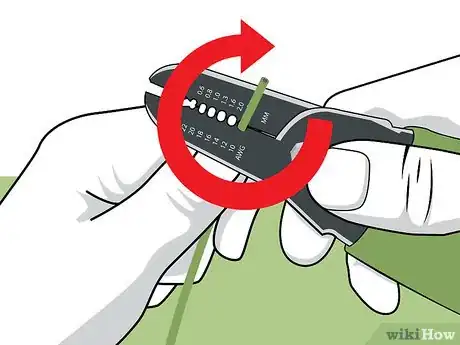

5Spin the tool around the wire to ensure you’ve cut the insulation. After you’ve closed the stripper’s jaws around the wire, carefully rotate the tool around the wire. This ensures the tool has cut through the entire circumference of the insulation.[6]

-

6Slide the stripper off the wire to pull off the insulation. Keep the tool’s jaws closed as you slide it off of the wire to remove the insulation from the tip. Pull the tool toward the short end of the wire, or the end that’s only about an inch (two to three centimeters) away from the jaws.[7]

Using a Utility Knife

-

1Hold the utility knife so it gently rests on the wire. Place the wire on a flat work surface. Use one hand to hold the utility knife about an inch (two to three centimeters) from one end of the wire. Don’t do any cutting yet, just let the knife rest on the exact spot you want to cut.[8]

-

2Roll the wire under the blade to score the insulation. Keep holding the knife with one hand. With your other hand, roll the wire so the blade scores all the way around the insulation sheathing.[9]

- You don’t want to press hard with the knife, or you could slice through the insulation and nick the metal conductors.

- It might take some practice before you can apply the correct amount of pressure, so consider trying the technique on scrap wires first.

-

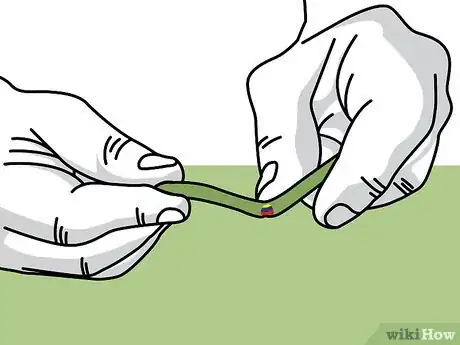

3Bend the wire at the scored line and break off the insulation. After scoring all the way around the insulation sheathing, you’ll probably have to do a little more work to strip it. Bend the tip of the wire up and down to break through the score completely. Once you’ve broken the insulation at the scored line, slide it off the tip of the wire.[10]

- Carefully scoring and bending the wire are useful if you want to reuse the wire in an electrical project. If you're scrapping it, it's easier to slice the wire lengthwise with a razor or use a wire stripping machine.

Stripping Wire for Scrap

-

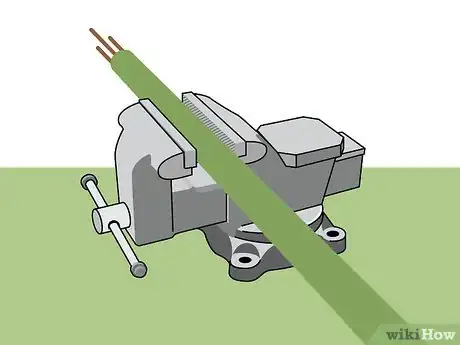

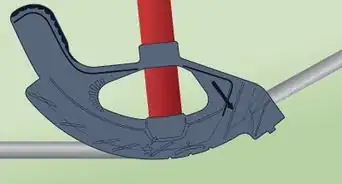

1Place one end of the wire in a vice. Use a mounted vice or clamps to hold the wire. That way, you'll be able to use both hands to cut the insulation and pull it away from the metal conductor.

-

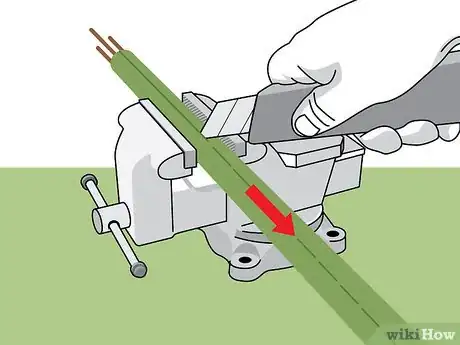

2Slice into the insulation with a sharp blade. Put on a pair of heavy gloves before you start to cut. Pierce the insulation near the end secured in the clamp with the point of a utility knife or razor blade. Slice down the length of the wire's insulation, and cut away from your body to avoid injury.[11]

- Since you're just selling the wire for scrap, you don't need to be as careful about nicking the metal conductor under the insulation.

- Use a flat-edged blade instead of a serrated knife. The teeth of a serrated blade would just make a mess instead of slicing cleanly through the insulation.

-

3Pull the insulation away from the metal conductor. Slice the wire lengthwise with one hand, and use the other to work the insulation away from the metal. Cut and pull the insulation off the end of the wire secured in the clamp. Grab that end of the insulation, and pull it off along as you slice the rest of the way down the wire's length.[12]

-

4Purchase a wire stripping machine for big jobs. If you have lots of wire, stripping it by hand can be tedious. At around $50 (US), tabletop manual machines are your most affordable option. If you are serious about scrapping wire and plan on stripping thousands of yards or meters per week, consider investing an automatic stripper.[13]

- Automatic machines can strip at least 200 feet (about 60 meters) per minute, but they cost several hundred dollars. Buying one will only be worth it if you regularly scrap wire in bulk.

Stripping Magnet Wire Using an Abrasive Surface

-

1

-

2Wrap the sandpaper around the end of the wire. Fold the sandpaper square in half around the tip of your wire. Position the sandpaper so it’s wrapped around the wire from the very tip to about an inch (two to three centimeters) up its length.[16]

- If you only have emery boards, just place one board on top of the wire’s tip and one under it.

-

3Pull the wire through the sandpaper to scrape off the coating. Use one hand to squeeze the sandpaper, and use your other hand to pull the wire through the sandpaper. Rotate the wire, then pull it through again so you scrape all around the surface. Keep pulling the tip of the wire through the sandpaper until you’ve stripped off the enamel coating.[17]

- Use the same pulling technique if you’re using emery boards.

- Repeat the process until you've stripped the desired length of coating off of the wire.

Expert Q&A

-

QuestionHow do I properly use wire strippers to remove insulation?

Ricardo MitchellRicardo Mitchell is the CEO of CN Coterie, a fully licensed and insured Lead EPA (Environmental Protection Agency) Certified construction company located in Manhattan, New York. CN Coterie specializes in full home renovation, electrical, plumbing, carpentry, cabinetry, furniture restoration, OATH/ECB (Office of Administrative Trials and Hearings/Environmental Control Board) violations removal, and DOB (Department of Buildings) violations removal. Ricardo has over 10 years of electrical and construction experience and his partners have over 30 years of relevant experience.

Ricardo MitchellRicardo Mitchell is the CEO of CN Coterie, a fully licensed and insured Lead EPA (Environmental Protection Agency) Certified construction company located in Manhattan, New York. CN Coterie specializes in full home renovation, electrical, plumbing, carpentry, cabinetry, furniture restoration, OATH/ECB (Office of Administrative Trials and Hearings/Environmental Control Board) violations removal, and DOB (Department of Buildings) violations removal. Ricardo has over 10 years of electrical and construction experience and his partners have over 30 years of relevant experience.

Electrician & Construction Professional, CN Coterie If you know the gauge of your wire, be sure to match it to the notch with the same number on the pair of strippers so you don't damage the metal.

If you know the gauge of your wire, be sure to match it to the notch with the same number on the pair of strippers so you don't damage the metal.

Warnings

- Always inspect the wire for damage after stripping if you’re using it for an electrical project.⧼thumbs_response⧽

- Work in a well-lit area when handling sharp tools.⧼thumbs_response⧽

- Wear work gloves when using sharp tools to prevent injury.⧼thumbs_response⧽

References

- ↑ https://www.familyhandyman.com/electrical/wiring/stripping-wire/view-all/

- ↑ Ricardo Mitchell. Electrician & Construction Professional, CN Coterie. Expert Interview. 6 May 2020.

- ↑ https://www.youtube.com/watch?v=TZFTKbT4XFs&feature=youtu.be&t=16

- ↑ https://www.bobvila.com/articles/how-to-strip-wire/#.WZM84lGGPb0

- ↑ https://www.youtube.com/watch?v=TZFTKbT4XFs&feature=youtu.be&t=36

- ↑ https://www.youtube.com/watch?v=TZFTKbT4XFs&feature=youtu.be&t=42

- ↑ https://www.bobvila.com/articles/how-to-strip-wire/#.WZM84lGGPb0

- ↑ https://www.bobvila.com/articles/how-to-strip-wire/#.WZM84lGGPb0

- ↑ https://www.bobvila.com/articles/how-to-strip-wire/#.WZM84lGGPb0

- ↑ https://www.familyhandyman.com/electrical/wiring/stripping-wire/view-all/

- ↑ https://iscrapapp.com/blog/how-to-strip-copper-wire-for-scrap/

- ↑ https://iscrapapp.com/blog/how-to-strip-copper-wire-for-scrap/

- ↑ http://shedheads.net/wire-stripping-machines-budget/

- ↑ https://www.youtube.com/watch?v=Pd5Q-XDmvys&feature=youtu.be&t=29

- ↑ http://www.ebay.com/gds/How-to-Strip-Magnet-Wire-/10000000205805408/g.html

- ↑ https://www.youtube.com/watch?v=Pd5Q-XDmvys&feature=youtu.be&t=45

- ↑ https://www.youtube.com/watch?v=Pd5Q-XDmvys&feature=youtu.be&t=50

About This Article

If you need to strip the ends off of a wire, place the wire into the appropriately-sized notch in a pair of wire strippers. Gently close the wire strippers around the insulation about 1 inch from the end of the wire. Squeeze the handles just enough to cut into the insulation and spin the tool in a circle so you make a cut all the way around the wire. Then, without easing your grip, pull the wire strippers sharply down to the end of the wire. The insulation should come free without damaging the wire. If you do accidentally cut into the wire, snip off that portion and start over. To learn how to strip wire for scrap, read on!