This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

This article has been viewed 95,906 times.

Learn more...

Many automotive projects require jacking your car up. Whether you are replacing a tire or trying to gain access to the bottom of the vehicle, a trolley jack can make lifting your car far easier than the scissor jacks that come with most cars. Trolley jacks roll beneath the car on four wheels and use hydraulic pressure to raise the car as you lift and press on the handle. Using the appropriate procedure when jacking up your car with a trolley jack will protect your vehicle from damage and you from getting hurt.

Steps

Preparing to Jack Up a Car

-

1Find a firm, even space to jack up the car. When you jack up a portion of the car, the weight of that portion will be centralized into the relatively small space beneath the jack. Because of this, it is essential that you jack your car up on a surface that can support that kind of pressure such as concrete or pavement. It is extremely unsafe to jack a car up on an angle, so it is also very important that you choose a level space.[1]

- Never, under any circumstances, jack a car up on angled ground.

- Jacking a car up on a surface that isn’t strong enough can cause the jack to topple over or sink.

-

2Ensure you have room to work safely. People often find themselves jacking up their car while replacing a flat tire on the road. Whether you’re using an emergency jack or a trolley jack, it’s important to ensure you have enough room to work without putting yourself or others at risk. Make sure you have at least enough room to stand with an outstretched arm toward the jack without coming into contact with a wall or being in the street.[2]

- You should be able to sit behind your jack without being in the lane of the road.

- If you do not have sufficient space, find a different area to jack your car up.

Advertisement -

3Insert a wheel chock. Wheel chocks can be purchased, but you can also use a number of things if you don’t have ready access to one. A wheel chock is usually shaped like a small ramp and is placed beneath a tire on the opposite end of the vehicle of the side you are jacking up. Always place the wheel chock on the outside end of the wheel to prevent the vehicle from rolling or shifting as you jack the other side up.[3]

- One wheel chock will usually suffice, but for added safety, feel free to chock the other wheel opposite the end you’re jacking up as well.

- If you don’t not want to purchase a wheel chock, you can use anything that will safely prevent the wheel from rolling, such as a large rock or block of wood.

- Plastic wheel chocks can be purchased at most auto parts stores.

-

4Ensure the car is in park. If your car is equipped with an automatic transmission, it should be in park before you jack it up. Putting your car in park prevents the wheels from turning. Remember, however, your car may still shift when in park, so it’s important to utilize wheel chocks in conjunction with placing the vehicle in park.[4]

- Remember that putting the car in park will lock its drive wheels in place, so a front wheel drive car’s front wheels won’t turn in park, and vice versa for a rear wheel drive vehicle.

- If your car is equipped with a manual transmission, try putting the car in first gear to prevent it from rolling.

-

5Engage the parking brake. Depending on your vehicle, the parking brake may be a handle in the center console of your car or a pedal on your left side when sitting in the driver’s seat. Pull up on the handle or press down on the pedal to engage the parking brake and prevent your vehicle from rolling while it’s being jacked up.[5]

- If you are unsure where your parking brake is or how to use it, refer to your car’s owner’s manual for help.

- The parking brake will lock the rear wheels in place and is of particular importance when jacking up the front of the car.

Jacking Up the Car

-

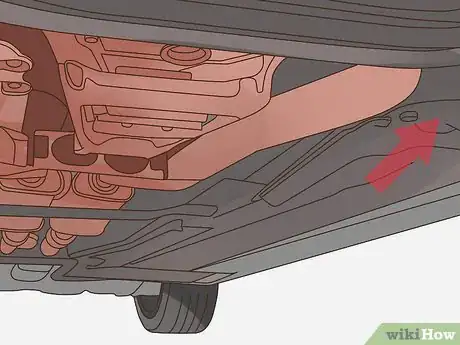

1Locate the appropriate jack points for your vehicle. Every vehicle has specific points on the frame that were designed to withstand the stress of jacking up the vehicle. These jack points are not always easily identified, so refer to your vehicle’s owner’s manual to help you find them if you are having difficulty.[6]

- There are commonly jack points on the frame of your car to the inside of each wheel, and at a center point on the front and back of the car.

- Jacking the car up at a point that is not designed for it can bend the frame of your car and cause significant damage.

-

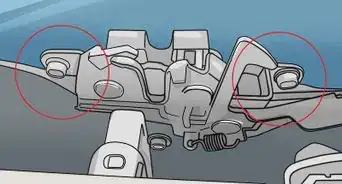

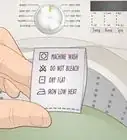

2Ensure the valve on the jack is closed. Trolley jacks utilize hydraulics to lift your vehicle off of the ground. When the hydraulic valve is open, the jack will not create pressure on the piston and it will fail to raise your car. Use the handle of the jack or a pair of pliars to turn the valve clockwise until it is completely closed. Re-insert the handle into the jack once done if you used the handle to close the valve.

- Different jacks may place the valve in different places, but it is often a different color than the rest of the jack or is left unpainted completely.

- The valve is usually located on the end of the jack that faces you while in operation.

-

3Slide the jack beneath the jack point. Slide your trolley jack beneath the jack point you’ve identified so the cup of the jack is sitting just beneath it. You may need to raise the cup of the jack slightly by lifting the jack handle and pressing it back down once to make sure the jack is positioned properly.

- The cup on the jack should be centered on the designated jack point for the vehicle.

- There are teeth or ridges on the cup of the jack to help prevent the car’s frame from sliding as it’s jacked up.

-

4Raise and lower the handle of the jack to lift the vehicle. Depending on the style and size of the trolley jack you are using, you may need to lift up the handle and press it toward the floor a number of times to jack up the car. Start slow, paying close attention to the frame around the jack point to look for signs of bending or crimping of the metal. Once you have lifted the car a few inches, you should be able to easily determine if the jack point is supporting the weight of the vehicle.

- It may take a good deal of force to press the handle of the jack toward the ground as it raises the car.

- If you see signs that the metal is bending, lower the car and reposition the jack unto the jack point properly.

-

5Lift the vehicle only as high as necessary. As you raise your car higher, you increase the risk associated with it falling off of the jack, as well as the likelihood that the jack itself will fall over or fail. If you are jacking the car up to change a tire, raise it only so the tire is barely off of the ground. If you need to get under the vehicle, ensure your jack can safely raise the vehicle to the height you intend.

- Trolley jacks have the maximum height and weight they are rated for on the packaging, and often on the body of the jack in the form of a sticker.

- Do not jack a car up until the arm of the trolley jack is standing straight up. It should always be slightly slanted.

Making the Car Safe to Work On

-

1Do not allow any part of your body beneath the vehicle on the jack. A trolley jack is not designed to support the weight of the vehicle while you work under it. Instead, trolley jacks are intended to raise the vehicle’s height so you can safely place jack stands beneath it. Never place a part of your body beneath a vehicle supported only by a jack.[7]

- As jacks get older, they often begin to leak.

- A leaking jack will lower the vehicle back onto the ground at a rate that can be unpredictable.

-

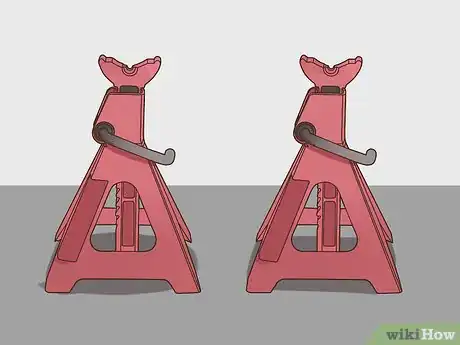

2Place jack stands beneath the vehicle. Before working on the car you jacked up, slide a jack stand beneath the car at a designated jack point. Jack stands are designed to support a great deal of weight and once in place they make it impossible for the vehicle to lower back to the ground. Lift the top of the jack stand until it’s at the height you prefer (slightly lower than the vehicle currently is) and slide it beneath a jack point.[8]

- You can purchase jack stands at your local auto parts store.

- If you are jacking up the entire front or back of the vehicle, use a jack stand on each side.

-

3Lower the car onto the jack stands slowly. With the jack stand in place, use the jack’s handle or a pair of pliars to slowly turn the valve on the jack counter clockwise. Be very careful, as the jack will lower the vehicle faster the further the valve opens. Make sure the jack stands are positioned properly before allowing the vehicle’s weight to rest on them.[9]

- If the jack stand is not positioned properly, raise the car again slightly and reposition it.

- Ensure all four legs of the jack stand are firmly on the ground and level before working beneath the car.

- Remove the jack while working on the car to prevent it from being raised off of the jack stands by accident.

-

4Raise the car off of the jack stands once you’re done. Once you’ve finished working on your car, slide the jack back into place beneath the vehicle. Close the valve completely, then raise and lower the handle until you have jacked the car up off of the jack stand. Once the weight of the vehicle is off of the stand, remove it and lower the car back to the ground. [10]

- Make sure the jack stands are clear of the car before lowering it back to the ground.

Community Q&A

-

QuestionHow do I lower the jack?

Community AnswerSlowly turn the jack arm. If you go too quickly the car will slam and that is just not good for it.

Community AnswerSlowly turn the jack arm. If you go too quickly the car will slam and that is just not good for it. -

QuestionHow to lower a trolley jack on a car?

Tinkerer02Community AnswerTurn the release valve on a hydraulic trolley jack. On small jacks, It is often a threaded bolt with a flattened or a square end. Fit the narrow end of the handle over the flattened end and slowly unscrew it to release the pressure. The car will come down. On larger jacks, there is a gear mechanism that engages the valve screw at the end where the handle fits on the jack. Turn the handle slowly anti-clockwise to unscrew the release valve. Tighten the valve after using, so that the jack can operate.

Tinkerer02Community AnswerTurn the release valve on a hydraulic trolley jack. On small jacks, It is often a threaded bolt with a flattened or a square end. Fit the narrow end of the handle over the flattened end and slowly unscrew it to release the pressure. The car will come down. On larger jacks, there is a gear mechanism that engages the valve screw at the end where the handle fits on the jack. Turn the handle slowly anti-clockwise to unscrew the release valve. Tighten the valve after using, so that the jack can operate.

References

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.familyhandyman.com/automotive/tires/car-repair-car-jack-safety/view-all#step1

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/

- ↑ http://www.dummies.com/home-garden/car-repair/how-to-safely-jack-up-your-vehicle/