wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 10 people, some anonymous, worked to edit and improve it over time.

There are 7 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 81,841 times.

Learn more...

There are three main types of bales that can be made for feeding livestock: small square bales, large square bales and large round bales. Large round bales are quite popular among many livestock producers, especially those who raise beef cattle, and the largest type of bale a producer can make to feed livestock. How large-round bales (LRBs) are made takes a good tractor, a round baler, and knowledge in how to maintain and operate such a machine to make the kind of bales you are wanting for your animals. This article covers how you can make LRBs for your animals.

Steps

-

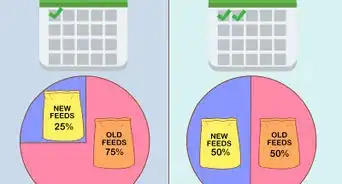

1Decide what type baler you want. Such companies that make balers include Vermeer, John Deere, Case IH, New Holland, etc. The type of baler you need depends on how large and heavy you want your bales to be, and also whether you want a soft-core bale or hard-core bale. Hard-core balers take less fuel and power to run than a soft-core baler. Also make sure that the baler is such that your tractor can handle the amount of horsepower (HP) it takes to run it.[1]

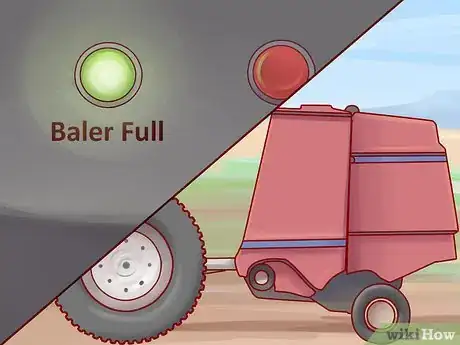

- Remember to purchase the computer to go inside the cab also to tell you when your bales are full, and when to tie.

-

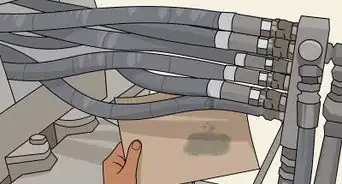

2Hook the baler up to your tractor. You will need to connect the hitch first, then the PTO and then the hydraulic hoses. Also connect the electrical components from the cab of your tractor to the baler.[2]

- Make sure your tractor is turned off or out of gear (in Neutral) before hooking up the PTO shaft. Also make sure the hydraulic hoses are hooked up to the right compartment so that you have control of to the right shift sticks on the tractor.

Advertisement -

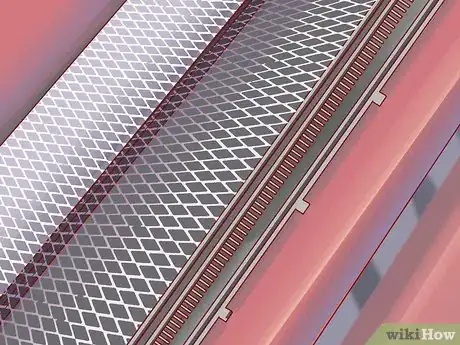

3Install the string or net wrap in the appropriate compartment. Make sure you thread the start of the string or net wrap to the appropriate area so the machine can take it and wrap the bale with it without trouble.

-

4Perform maintenance checks before beginning to bale. Make sure that your belts are tight and chains and grease fittings greased. Only 4 pumps of grease for each fitting is necessary. Your baler will last longer if you check it and grease it before baling.[3]

-

5Drop the pick-up wheels from each side of the baler and make sure that they are barely touching the ground. However, if the grass is somewhat damp you want the wheels as low as they can go.

-

6Turn your PTO on with the throttle all the way back (at idle or turtle). Stop right before you get to the initial swath. Slowly turn up the throttle. The more you rev up the throttle to the engine, the faster the reel will spin and the more hay you can pick up as you drive along.

-

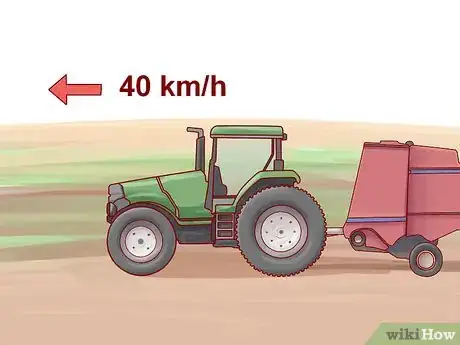

7Drive forward, keeping your speed down between 20 or 40 km/h (12 or 25 mph). You want to straddle the swath between the tires, so that you are pretty much on top of the swath with your tires on either side of the swath. Remember to go at a slower speed for thicker or wetter swaths, but also don't go so fast that you are getting too reckless with your machinery. Take your time, but keeping so that you are going at the right speed in time with the speed you have the pick-up reel at.

-

8Bale away. Keep your on eye on the pick-up reel and belts from your viewpoint of the tractor for any signs of any mishaps. You will get plugged up: it's not a matter of if, but when, no matter how slow you're going or how dry the hay is. Also keep an eye on the computer to see how full the baler is getting, and what's in front if you to keep the tractor in a straight line.

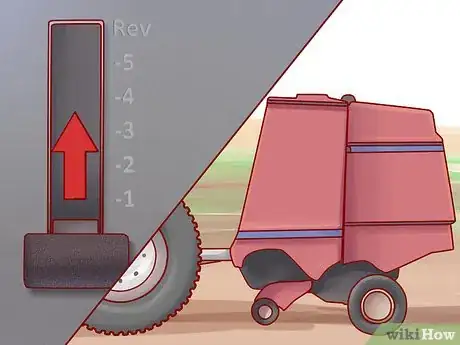

- If you get plugged up, STOP, and back up a little to allow room for the reel to work without interfering with the swath There's a switch on your the computer that allows the pick-up reel to reverse to help spit out the hay that has plugged up the baler. Use this, reversing a half to full revolution at a time, then going back forward again, until the plug is cleared.

- If this doesn't work, use a thick, stout and long stick (around 5 feet in length and 2 inches in diameter) to push the gummed-up fodder into the baler. You will need to keep the baler in-gear to allow the reel to put the fodder into the baler, but not at so high a gear that it is very dangerous for you.

- If neither the reversing reel or stick method works, shut down the baler, and tractor and attempt to manually pull out the hay yourself. If you so choose, you can either unplug the baler right in the hayfield, or drive up to the corrals where your livestock will be able to visit so you can take the fodder you pulled out of the baler and throw it over the fence to them. Use your judgement to determine whether the amount you pulled out is enough to help unplug the baler. If it has, great! If not, best to keep working at it.

- Once you've unplugged the reel, get in the tractor, back up just a little bit, rev up the engine, and SLOWLY move the pick-up to the pile of hay, letting the reel pick up a little at a time. Never ever rush getting through a large pile of hay, as you will get more plug-ups doing that than being overly cautious.

- If neither the reversing reel or stick method works, shut down the baler, and tractor and attempt to manually pull out the hay yourself. If you so choose, you can either unplug the baler right in the hayfield, or drive up to the corrals where your livestock will be able to visit so you can take the fodder you pulled out of the baler and throw it over the fence to them. Use your judgement to determine whether the amount you pulled out is enough to help unplug the baler. If it has, great! If not, best to keep working at it.

- If this doesn't work, use a thick, stout and long stick (around 5 feet in length and 2 inches in diameter) to push the gummed-up fodder into the baler. You will need to keep the baler in-gear to allow the reel to put the fodder into the baler, but not at so high a gear that it is very dangerous for you.

- Once you're through, then you can continue baling.

- If you get plugged up, STOP, and back up a little to allow room for the reel to work without interfering with the swath There's a switch on your the computer that allows the pick-up reel to reverse to help spit out the hay that has plugged up the baler. Use this, reversing a half to full revolution at a time, then going back forward again, until the plug is cleared.

-

9Let the baler get full enough. Once the signal on your on-board computer starts going that your baler is getting full, you can choose to keep going for another few minutes or so until you can clearly see the baler is getting quite full. Ideally you should have your bales as tightly baled up as possible to prevent less moisture from getting in the bales when stored outside.

-

10Put the strings on. When you are sure that the baler is full enough, stop the tractor, but keep the baler running via PTO and hydraulic hoses. Turn the switch on that's found on the computer to put the strings on the bale. Allow for four to five revolutions to completely tie the bale. Two to three revolutions is enough for putting net on. Switch off the switch that lets the string run, and this should cut the string from the string box on the baler.

-

11Empty bale from the baler. Turn the switch that opens the back of the baler. Then turn on the belts and drive forward a few feet, letting the bale out. Turn off the belts, drive forward a few more feet so you have enough room to shut the back door of the baler. Turn the switch on the computer to shut the baler.[4]

-

12Test the bale for moisture.[5] Turn off the baler and put the tractor out of gear (neutral), get out with the soil tester and get a reading from the middle of the bale to see what the moisture content is. Ideal moisture content should be around 20%.[6]

- You will need to test moisture content every three to four bales, or when you get baling swaths that are a bit thicker than the others.

-

13Rev up the engine, turn the belts back on again and continue baling your second bale. Repeat Steps 6 to 11, performing Step 12 every few bales, or as often as necessary.

Community Q&A

-

QuestionI have a Vermeer 505L round baler that I purchased used. When looking back at my baler from my cab, where should the string indicator be when beginning a bale? Should it be on the left, or right?

Community AnswerThe indicator should be towards the right of the baler. When activated, it swings to the left and begins the tie.

Community AnswerThe indicator should be towards the right of the baler. When activated, it swings to the left and begins the tie.

Warnings

- ALWAYS keep yourself away from a running PTO shaft. That means arms, legs, loose clothing and loose hair. It's not pretty nor a great way to die if you get caught on a PTO shaft.

- NEVER EVER REACH OVER A RUNNING PTO SHAFT. You could and will die, especially if you get your arm or clothes caught on it.

⧼thumbs_response⧽ - NEVER EVER push in plugged-up fodder with your hands!!! You will get caught and wrapped up in the bale, and never ever get out again. This means certain death if you do such a thing with a running machine.⧼thumbs_response⧽

References

- ↑ https://www.extension.iastate.edu/smallfarms/buyers-guide-hay-equipment

- ↑ https://www.youtube.com/watch?v=1uwpWTxcIxk

- ↑ https://www.recyclingtoday.com/article/6-baler-maintenance-tips-for-recyclers/

- ↑ https://www.youtube.com/watch?v=QamNKNQuua0

- ↑ https://cropwatch.unl.edu/using-microwave-oven-test-moisture-content-forage-unl-cropwatch-aug-9-2012

- ↑ https://www.alberta.ca/bale-moisture.aspx

- https://extension2.missouri.edu/g4575