This article was co-authored by Jason Williams and by wikiHow staff writer, Amy Bobinger. Jason Williams is an AV & Security Specialist and the Owner of Williams AV & Security. With more than 35 years of experience, he specializes in home automation and home theater system installations. Jason is an AVIXA Certified Technology Specialist, a CEDIA Certified Cabling & Infrastructure Technician, a Pakedge Certified Network Administrator, and holds a Georgia Low Voltage Unrestricted License.

There are 14 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 535,641 times.

You've found the perfect spot for your speakers and stereo equipment, and now you're ready to hook it all up—but your speaker wire isn't long enough to connect it to the amp. For a quick fix, you can twist the wires together and tape them. This isn't a great long-term option though, because the wires can pull apart and short out your system.[1] For a more permanent solution, use crimp connectors or solder the wires together.

Steps

Cutting and Stripping

-

1Double-check that your speaker is disconnected before you start. Unplug the power to the speaker and disconnect the speaker wire from your amp. If there's any power running to the speaker, you could be seriously hurt when you start working with the wires.

-

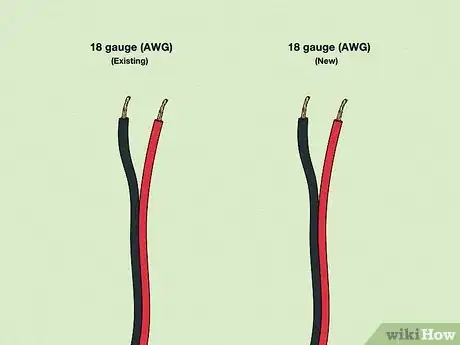

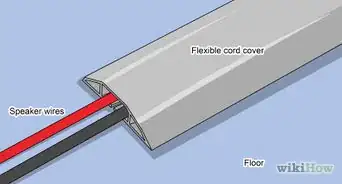

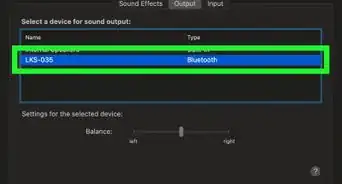

2Match the size of your replacement and existing wire. For the best sound results, use stranded (not solid) speaker wire that's the same gauge (AWG) as your existing wire. Some wires will have the gauge printed down the side of the wire. If yours doesn't, place the wire in the holes of your wire cutter until you find the hole it fits in most closely. The number that's printed beside that hole is the wire gauge.[2]

- You can also cut a small piece of the wire and take it with you to a store that sells audio supplies so they can tell you.

- Speaker wire ranges from 10AWG (which is very thick) to 20AWG (which is very thin). 18 gauge (AWG) is the most popular size, and it's usually used for distances of up to 25 ft (7.6 m). 16 gauge is also common, especially for distances up to 50 ft (15 m).[3]

- You can splice 2 differently-sized wires together, as long as they're close in gauge (like 18AWG and 16AWG).

- If the extension of the wire is beyond 100 feet, consider replacing the wire with a thicker size.

Advertisement -

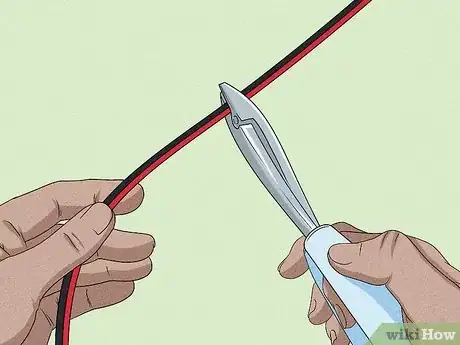

3Measure and cut your extra speaker wire. Use a tape measure to find how much extra length you need on your wire. However, add at least 1–2 ft (0.30–0.61 m) to that measurement. You'll need a little extra slack in the wire, since too much tension could damage the connection on your speakers or amp or cause the wire to pull free.[4] Then, use wire cutters to cut the extra speaker wire to that length.[5]

- Many wire strippers also act as wire cutters, so you may not need two separate tools for this.

- Consider off-setting the cuts on the negative and positive wire instead of cutting them straight across. For instance, you might make the positive end of the existing wire 2 in (5.1 cm) longer than the negative. Then, on the extension wire, you'd cut the positive side 2 in (5.1 cm) shorter than the negative. This off-set will make the finished wire less bulky, and there's no chance the positive and negatives will touch.[6]

-

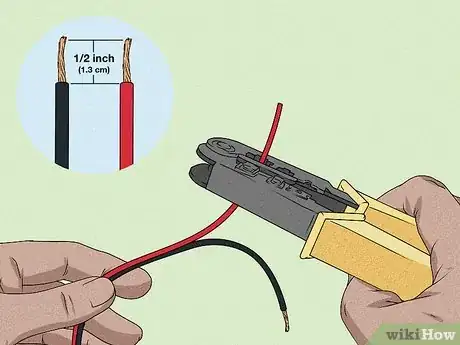

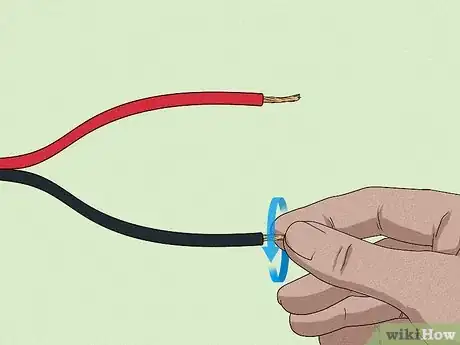

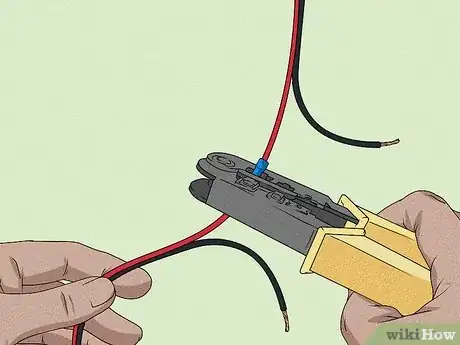

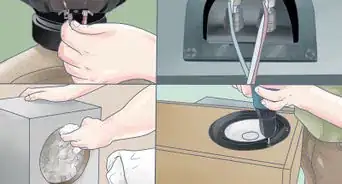

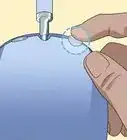

4Strip the ends of both pieces of wire. Your speaker wire should look like 2 small tubes attached together. Carefully pull these apart, so the wire forms a Y shape. Then, clamp a wire stripper about 1⁄2 in (1.3 cm) from the end of the wire—squeeze just firmly enough to hold the wire in place, but not so tightly that you damage the wire beneath. Pull the wire firmly with your free hand. The insulation should slide off, exposing the bare wire without damaging it.[7]

- Do this for both the positive and negative sides on the extension wire.

- If the bare wires are already exposed on your existing speaker cord, you may not need to strip them again. If the wires look frayed, though, it's a good idea to cut them shorter and strip them so you have a fresh piece of wire to work with. Cut the wire as close to the frayed pieces as possible.

Twisting and Taping

-

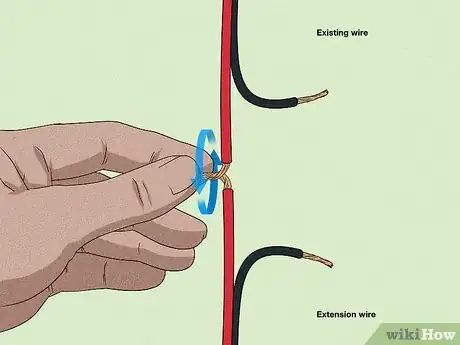

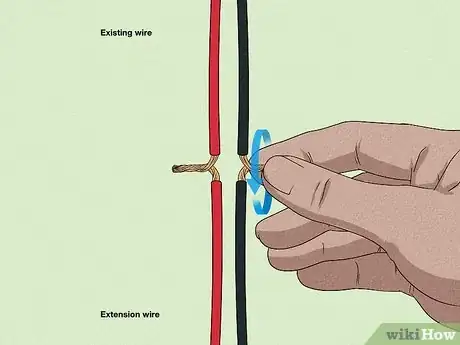

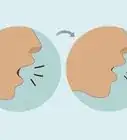

1Twist the positive ends of the two wires together. Find the positive sides of your existing wire and the extension. Use your fingers to gently spread apart the strands that make up the wire to increase the contact between the two wires. Interlace the two bare pieces of wire through each other at the base so they make a V shape, then twist them together in a clockwise motion until they're connected tightly.[8]

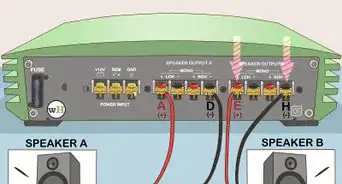

- If there's any identifying feature on one side of the wire—like if one side is black and the other is colored, or if one side is striped, printed, stamped, or molded—that's the positive side. Also, if one side of the wire is silver and the other is gold, the gold side is positive.[9]

-

2Connect the negative ends of the wires. Take the two remaining pieces of bare wire on your extension. These will be the two negative sides. Twist these sides together just like you did for the positive ends—interlace the strands in a V shape, then spin the wires until they're wound together tightly.[10]

-

3Wrap each set of wires in electrical tape. Starting on the positive wires, wrap a piece of tape around the insulation on one side of the connection. Keep wrapping the tape over itself in a spiral until you've completely covered all of the bare wire.[11] Then, repeat that on the negative side of the wires.

- Do not leave any bare wire showing at all. If the positive and negative sides of the wire touch, your speaker could short out and be permanently damaged. You'll also risk being shocked if you touch the bare wire while the speaker is on.[12]

- Give each set of wires a light tug to make sure they're secure after you tape them.[13]

-

4Go around the whole wire with more tape. Although all of the bare wire is now covered, you still have two separate pieces of wire that are split in the middle. This could potentially create a weak spot in the wire, so press the two sides together and wrap the whole thing in more electrical tape to create a secure single wire.

- Although this will help stabilize the wire, the connection could still loosen over time, especially if you move the wire or put a lot of pressure on it. Eventually, that could cause a short that could damage your stereo equipment.[14]

Crimping the Connector

-

1Twist each bare end of wire tightly. Don't worry about connecting the wire yet. Just use your fingers to twist the positive and negative ends of both pieces of wire until you can't see any individual strands.[15]

-

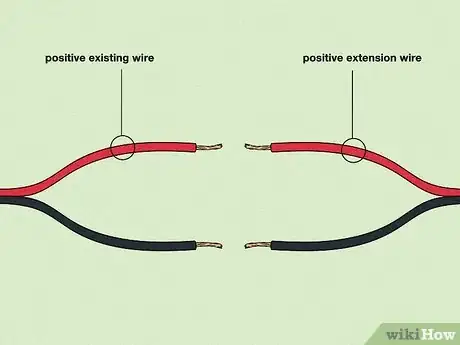

2Identify the positive ends and negative sides of the wires. Look at your speaker wire and find the side that's red, gold, printed, or stamped. This is the positive side. Find the positive end of the extension wire, as well. Be sure to keep track of which side is which—if you attach a positive wire to a negative one, you could short out your speakers, permanently damaging them.[16]

-

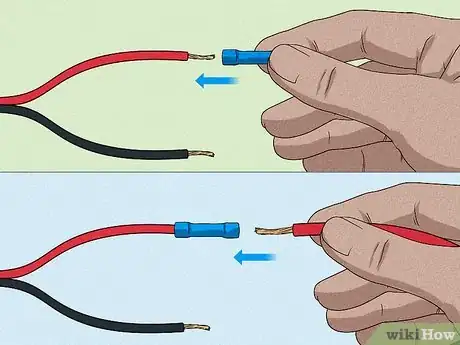

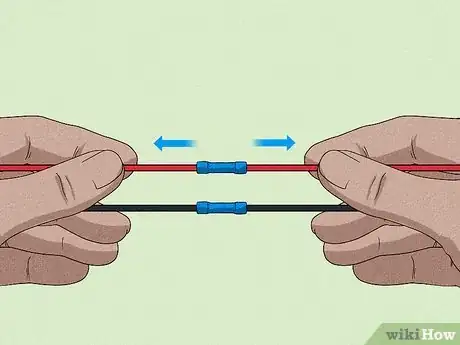

3Push each set of wires into a crimp connector. Insert the positive end of your existing speaker wire into the first crimp connector as far as the bare wire will go. Then, insert the positive end of the extension wire into the other end of the connector. Put the negative ends of the wires into a second connector in the same way.[17]

- Double-check that there isn't any bare wire showing on either side. If there is, pull that end of the wire out of the connector and cut the bare wire a little shorter.

- Make sure you choose the right crimp connector for your type of wire. They're usually color-coded—yellow for 10-12 AWG, blue for 14-16 AWG, and red for 18-22 AWG. You might see crimp connectors called butt connectors or butt splices—these terms all refer to the same thing!

-

4Clamp down on each connector with a crimp tool. A crimp tool looks similar to a wrench, but it has spaces in its jaws where you can place a wire. Place one end of the crimp connector into one of these channels, then press down hard on the tool to crimp the connector onto the wire. Do the same on the other side of the connector.

- Crimping the connector will lock it onto the wire, creating a permanent splice.

- Don't use pliers or any other tool to crimp the wire—it won't hold the connector securely in place.[18]

-

5Double-check your connection by pulling on the wire. With the wire still held in the crimping tool, gently pull on the wire. If it comes loose, it wasn't secured and you'll need to start over with a new connector.[19]

- After you check that the wires are secure, you can wrap the connectors in electrical tape for extra stability. Don't use the tape to stabilize poorly-secured connectors, though.

-

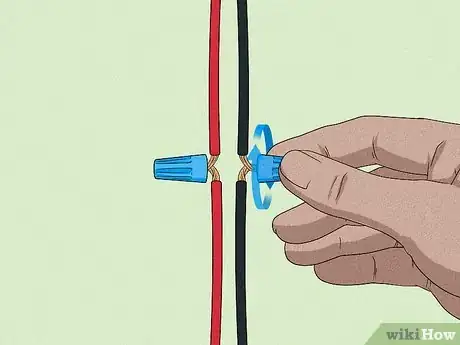

6Try a wire nut as a quick alternative to a crimp connector. Wire nuts work similarly to crimp connectors, but they aren't quite as secure. Just push the positive ends of the wires side-by-side into a wire nut, then turn the nut clockwise to intertwine the wires. Do the same for the negative sides.

Soldering the Wire

-

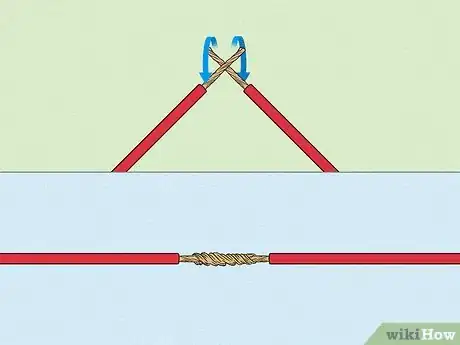

1Twist the positive ends of each wire together. The positive side of the wire will be printed or stamped, or it may be red (the negative side will be black) or gold (the negative side will be silver). Lay the bare ends of each positive wire over each other to form an X. Then, rotate one side of the wire toward you and the other side away from you to twist the two wires together.[20]

- Keep twisting until the wires are connected firmly together.

- Tuck the ends of the wire in neatly—if they're sticking up, they could pierce through the electrical tape you use at the end.

-

2Use clamps to hold your wire off of your work surface. Solder uses high heat, so it's important not to place the wires directly on a surface that could be damaged, like a wooden table. Try using a helping hands device to lift the wires—it's a small device with two metal clips that will hold the wire in place.[21]

- If you don't have a helping hands device, you can improvise by clamping the wire between two alligator clips, then standing the clips on end. This won't be super-secure, though, so try not to bump the clips or the wire while you're working.

- You could also work on a heat-safe surface, like a metal or concrete workbench.

-

3Melt solder onto the bare wires. Place the tip of a hot soldering iron to the bare, twisted wire. At the same time, place a stick of solder against the wire. Once the iron heats the solder enough, the solder will melt, flowing over and into the speaker wire. Coat the wire completely in the solder from one end to the other.[22]

-

4Flip the wire over and repeat this on the bottom. Unclamp your wire and turn it over so the bottom is exposed. Then, melt solder over this side as well, until the bare speaker wire is completely covered.[23]

- If you have enough room to maneuver beneath the wire, you could just hold the soldering iron and solder under the wire and melt it that way, rather than flipping the wire over.

- Once you've soldered the wire, let it cool for 5-10 minutes before you handle it.

- Repeat the whole process to connect the negative sides of the speaker wire.

-

5Wrap the wire in electrical tape. Even though there's solder coating the wire, it still needs to be insulated—the solder is conductive, so if the positive and negative sides touch, the wire will short out. Wrap the whole splice in electrical tape, going from one end of the insulation to the other. Do this for both the positive and negative sides of the wire. To create a cleaner look, you can then pinch the positive and negative sides together, then wrap the whole thing in electrical tape as well.[24]

- You can also use heat shrink tubing to insulate the wires. Put the tubing on the wire before you splice the ends together, but keep it away from the heat of the soldering iron. Once the solder is cool, slide the tubing over the splice and use a heat gun or hair dryer to shrink it around the bare wire.[25]

Expert Q&A

-

QuestionCan I splice different gauge speaker wire?

Jason WilliamsJason Williams is an AV & Security Specialist and the Owner of Williams AV & Security. With more than 35 years of experience, he specializes in home automation and home theater system installations. Jason is an AVIXA Certified Technology Specialist, a CEDIA Certified Cabling & Infrastructure Technician, a Pakedge Certified Network Administrator, and holds a Georgia Low Voltage Unrestricted License.

Jason WilliamsJason Williams is an AV & Security Specialist and the Owner of Williams AV & Security. With more than 35 years of experience, he specializes in home automation and home theater system installations. Jason is an AVIXA Certified Technology Specialist, a CEDIA Certified Cabling & Infrastructure Technician, a Pakedge Certified Network Administrator, and holds a Georgia Low Voltage Unrestricted License.

AV & Security Specialist Anytime you extend a wire, you're creating a break in the signal chain, and the proper way to make a speaker wire longer is to replace it. It that's not possible, then it should be extended with the same gauge speaker wire.

Anytime you extend a wire, you're creating a break in the signal chain, and the proper way to make a speaker wire longer is to replace it. It that's not possible, then it should be extended with the same gauge speaker wire. -

QuestionIs it safe to join the wires with electrical tape?

Community AnswerYes. Twist them together first, then apply the electrical tape. It may not be the most secure way of joining the two cables, but it will work. Make sure not to tug or pull on them, as they may easily come undone. There shouldn't be too high of a voltage in your stereo system, so don't worry about deadly, electrical shock.

Community AnswerYes. Twist them together first, then apply the electrical tape. It may not be the most secure way of joining the two cables, but it will work. Make sure not to tug or pull on them, as they may easily come undone. There shouldn't be too high of a voltage in your stereo system, so don't worry about deadly, electrical shock. -

QuestionDoes the extension cable need to be the same length on each speaker?

Community AnswerNo, you can have any combination of lengths, really. There could be a slight change in volume from one speaker to another because there is a power loss from a extremely long cable, but it's unlikely. Also, there might be a slight lag between speakers, but it will probably be undetectable by human ears.

Community AnswerNo, you can have any combination of lengths, really. There could be a slight change in volume from one speaker to another because there is a power loss from a extremely long cable, but it's unlikely. Also, there might be a slight lag between speakers, but it will probably be undetectable by human ears.

Things You'll Need

Cut and Strip

- Extra speaker wire

- Measuring tape

- Wire cutters/strippers

Twist and Tape

- Electrical tape

Crimp Connector

- Crimp connector

- Crimping tool

- Electrical tape (optional)

Solder

- Metal clamps or helping hands

- Soldering iron

- Solder

- Electrical tape or heat-shrink tube

References

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/tXrESwKh_4I?t=13

- ↑ https://soundcertified.com/what-size-speaker-wire-guide/

- ↑ https://davidmassengill.com/how-to-extend-speaker-wire/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ http://millardlumber.com/HowTo/soldering/solder.htm

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/f0Gierk4SCw?t=66

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/f0Gierk4SCw?t=66

- ↑ https://youtu.be/f0Gierk4SCw?t=112

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/f0Gierk4SCw?t=147

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/Svja8zEcKNQ?t=37

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://youtu.be/Zu3TYBs65FM?t=482

- ↑ https://youtu.be/Zu3TYBs65FM?t=519

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://soundcertified.com/how-to-extend-speaker-wire-guide/

- ↑ https://www.popularmechanics.com/cars/a1430/4213013/