wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 9 people, some anonymous, worked to edit and improve it over time.

There are 7 references cited in this article, which can be found at the bottom of the page.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 89% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 83,234 times.

Learn more...

Woodworking can be a fun, relaxing passing time, or even a career for individuals who have the skills and patience to work for themselves. Having a workshop set up properly will improve your experience regardless of what level you aspire to work at.

Steps

-

1Make sure the room or building you plan to use is large enough. Once you have spent time planning and installing your equipment, it is an awful feeling to realize you can't function effectively in your shop. Here are some basic items to consider when you plan your shop.

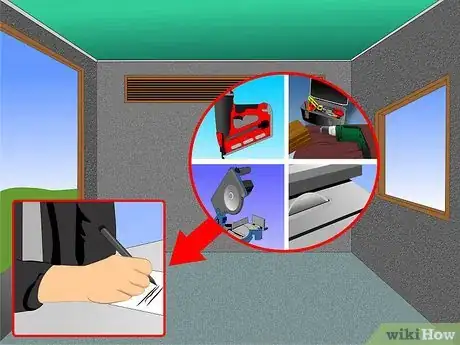

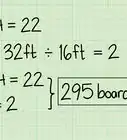

- List the major tools you plan to install in your workshop, using the footprint and user space required for each. Here are examples:[1]

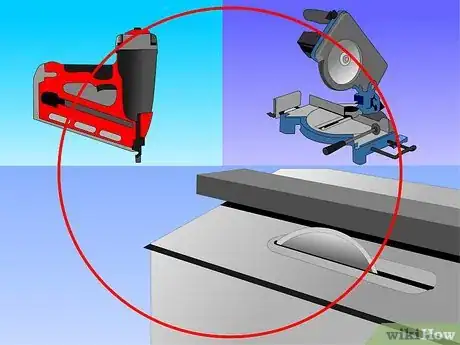

- Table saws are about four feet by four feet, and require room to stand and feed material from at the front, and room to allow material to discharge after it has been cut. This means you need an area over six feet wide, and at least ten feet long for this one machine.

- Miter saws are generally smaller machines, as small as two feet wide and two feet deep, and the lumber is put in front of the saw to be cut, so you need at least six feet of width, and two feet of depth for this machine.

- Band saws and scroll saws are fairly small machines as well, and for cutting small items, they can be operated in a space of about three feet by five feet when they are set up on an independent stand built for them.

- Table mounted routers, planers and shapers are another machine that usually has material fed through, and although they are fairly narrow machines, they require room on their front for material to be fed from, and at the rear for the material to be removed after the work is complete, so again, a space of about ten feet is needed for any significant work.

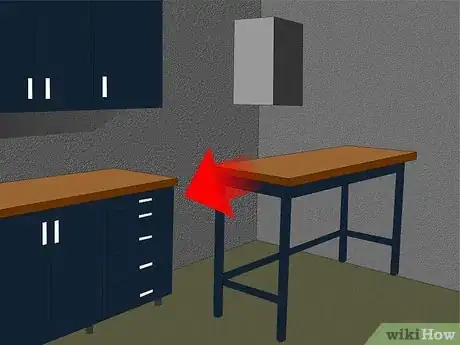

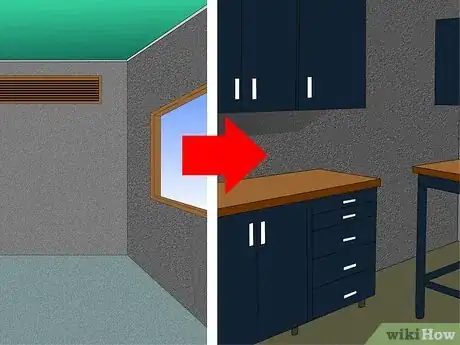

- Look at bench and table space you will need for assembling projects and mounting bench top machines. A workbench about three feet deep and six feet long will do for many ordinary projects, but most woodworkers would rather have too much space than to be crowded with too little.

- Consider how you will store material if you plan on storing more than just what you will use on individual projects, and remember, it is often less expensive to buy in larger quantities, and having spare material in the event of a mistake can keep a project going, rather than taking a trip to the local lumberyard.

- List the major tools you plan to install in your workshop, using the footprint and user space required for each. Here are examples:[1]

-

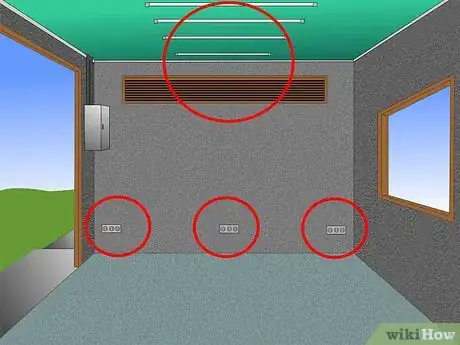

2Make sure the room or building you are planning to utilize has sufficient lighting and electrical outlets to allow you to see what you are doing, and to work without excessive extension cords. You should also remember that many tools require a fairly substantial amperage to operate, so you need to make sure the wiring is capable of handling the loads. 20 Amp circuits will work for ordinary 120V tools, but air compressors and welders may require 40 Amp, 220V circuits.Advertisement

-

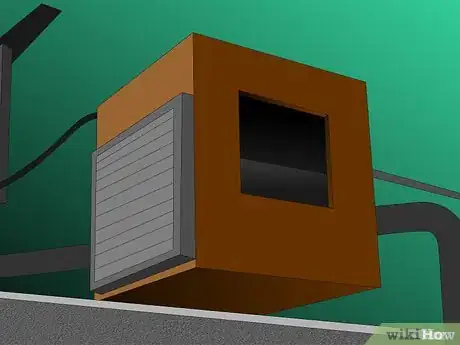

3Insure the workshop has adequate ventilation. Cutting and sanding produces a lot of dust, and you may find it is difficult to breathe when the atmosphere is full of this stuff. Also, when using paints, stains, and adhesives you can find an explosive atmosphere is possible if ventilation is not maintained.[2]

-

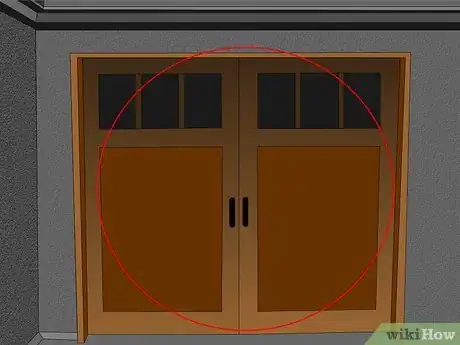

4Check the size of your door opening, especially if you are going to finish large projects that will need to be removed after completion. A roll-up door is wonderful if you can swing it, a double door will work, but if possible, plan to have at least a three foot door for your main entrance.[3]

-

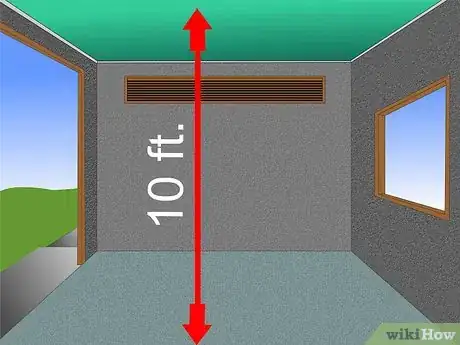

5Look at your ceiling height. A standard eight foot ceiling is fine for a residence, but flipping an eight foot sheet of plywood in a workshop with an eight foot ceiling is next to impossible. If you are building your shop from scratch, consider a ten foot ceiling.

-

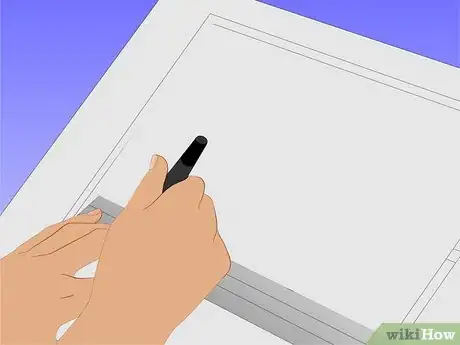

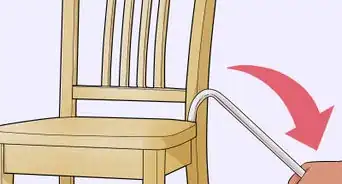

6List the tools you plan to install in your workshop, and draw a scale drawing of your floor plan showing the footprint of each machine, allowing room for working around it as needed. Leave walkways around the machines, and estimate the space handling materials will require for each.[4]

-

7Look for portable or semi-portable machines if you find you cannot accommodate full sized stationary machines. You can also compromise by installing combination machines that can perform the job of more than one, single purpose machine.

-

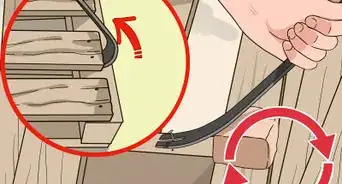

8Look at specialized storage cabinets to keep small parts, fasteners, and small tools organized and out of the way.

-

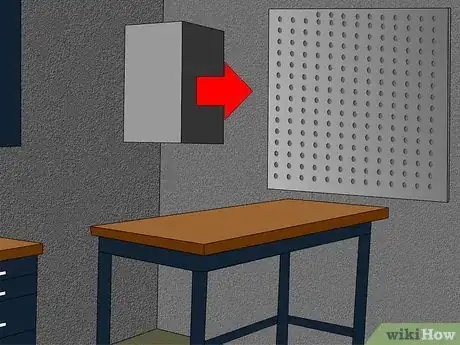

9Consider installing peg board panels behind workbenches or on walls where hand tools and other items can be hung for easy access.[5]

-

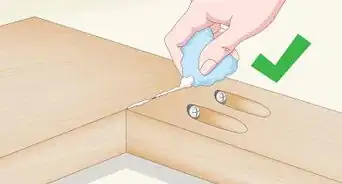

10Begin building or remodelling the space you plan to use for your workshop with an understanding that very few wood workers have the luxury of a shop with all the room and equipment they will ever need, and sacrifices and compromises are almost inevitable, but planning and coordination will make the process easier and more successful.[6]

Community Q&A

-

QuestionWhat's the best material to use on interior walls of a new woodshop?

Community AnswerI like 3/8" plywood. You can screw tool boards, pegboard, all sorts of cabinets and small boxes to it and not worry as much about tear-out as drywall. Be sure to use nail plates where appropriate; you don't need those kinds of surprises. Also, paint your walls and ceiling a semi-gloss light color to maximize the lighting efficiency in your shop.

Community AnswerI like 3/8" plywood. You can screw tool boards, pegboard, all sorts of cabinets and small boxes to it and not worry as much about tear-out as drywall. Be sure to use nail plates where appropriate; you don't need those kinds of surprises. Also, paint your walls and ceiling a semi-gloss light color to maximize the lighting efficiency in your shop. -

QuestionIn priority order, for general outdoor wooden furniture construction, what power tools (stationary, not portable) should I have?

AgewalkerCommunity AnswerYou absolutely should have a miter saw. A bandsaw and table saw are also good general-use tools, but past that, it depends on what you are planning on making.

AgewalkerCommunity AnswerYou absolutely should have a miter saw. A bandsaw and table saw are also good general-use tools, but past that, it depends on what you are planning on making.

Warnings

- A fire extinguisher by each exit door can be a life/shop saver.⧼thumbs_response⧽

- A First Aid Kit and a telephone are important, especially if you work alone.⧼thumbs_response⧽

- If you are a beginner you might want to print out some safety rules and post them on or by the particular machine.⧼thumbs_response⧽

- Create your workshop with safety in mind. This includes making sure electrical power is sufficient, dangerous fumes can be ventilated out, and saws and other equipment has sufficient room to be operated safely.⧼thumbs_response⧽

- Install a smoke/carbon monoxide alarm or two if your shop is above 40 °F (4.4 °C). They may not work below 40 degrees.⧼thumbs_response⧽

Things You'll Need

- A very good plan of what equipment and working space your needs require.

- Drawing paper and a measuring tool to draw up your floor plan.

- Sometimes it is easier to draw the footprint of the machine on the floor with chalk. Use another color to draw the necessary working space around the footprint.

References

- ↑ https://www.youtube.com/watch?v=0OQyP7LK0QE

- ↑ https://www.finewoodworking.com/2012/12/17/all-about-dust-collection

- ↑ https://www.youtube.com/watch?v=Vnaf5UQEeZU

- ↑ https://www.woodworkingnetwork.com/best-practices-guide/solid-wood-machining/setting-shop-most-useful-power-tools

- ↑ https://www.thewoodwhisperer.com/articles/12-shop-layout-tips/

- ↑ https://www.bobvila.com/articles/2031-planning-your-woodworking-shop/

- https://www.youtube.com/watch?v=atq41N3whTM