wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 10 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 150,045 times.

Learn more...

When wood is cut from a living tree, it is saturated with moisture. As this water dries from the wood, the wood will contract in shape unevenly, due to the differing shapes and sizes of the wood's cells. Therefore, to keep your woodworking projects from warping, cracking, or otherwise becoming distorted, you need to dry the wood thoroughly before using it. Learning how to dry wood for woodworking is a simple and inexpensive process, but it does require a long waiting period for especially moist wood.

Steps

-

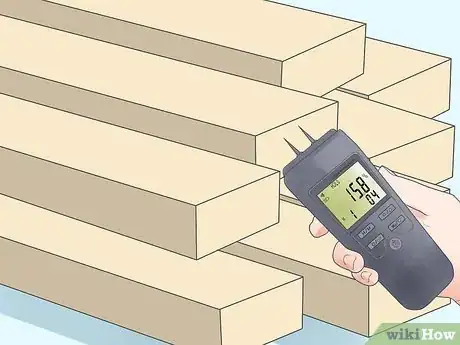

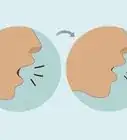

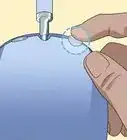

1Purchase a moisture meter. There is no accurate visual or tactile test for determining a wood's moisture content. To be sure that your wood is dry enough for woodworking, you'll need a small handheld tool called a moisture meter. This tool has 2 small metal probes that are touched against the wood to produce a moisture readout expressed as a percentage of the wood's volume or weight.

-

2Test the wood's moisture content. Use the moisture meter according to the manufacturer's directions. The acceptable moisture content for most woodworking projects is about 6 or 7 percent. If your wood gives a readout much higher than that, you'll know it needs to dry before being used.[1]Advertisement

-

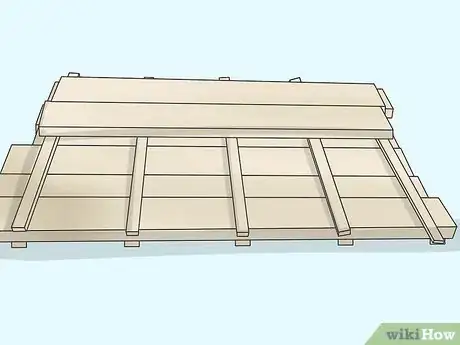

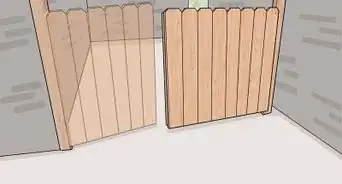

3Lay out a row of stickers on which to dry the wood. "Stickers" are simply 1" x 2" (25 x 50 mm) pieces of lumber that are used to provide airflow between the boards you are drying. Lay each sticker about 16 inches (40 cm) apart and line them up parallel to each other. You'll need enough stickers to support the entire length of the boards you are drying.[2]

-

4Stack the first layer of boards. Carefully set the first layer of wooden boards on top of the stickers, running them perpendicular to the stickers. Leave an inch or so of space between each board to allow for increased airflow.

-

5Continue stacking stickers and boards. Next, you'll place another row of stickers on top of the boards, lining them up directly with the previous set of stickers. Continue alternating stickers and boards until you've accommodated all of the wood you need to dry. You should now have a nice stack of wood boards that are separated from each other in all directions to provide circulation.[3]

-

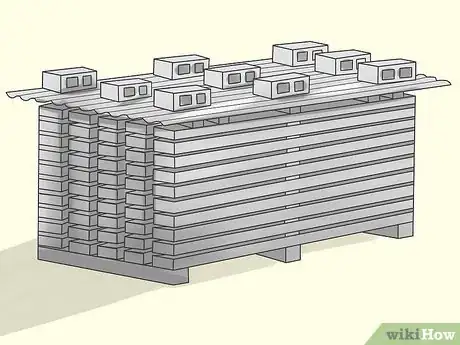

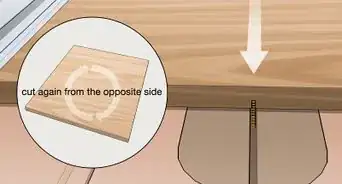

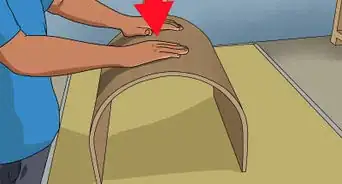

6Position a heavy sheet of plywood over the stack. You'll need to apply some downward pressure to the stack to keep it from warping upwards as it dries. To do this, place a thick sheet of plywood on top of a final set of stickers. Stack a few concrete blocks or other heavy objects on top of the plywood for additional weight.[4]

- This setup is also ideal for deflecting rain if you are drying the wood outdoors.

- Do not cover the drying wood with a tarp or other overhanging fabric, as this tends to prevent airflow and trap in moisture.

-

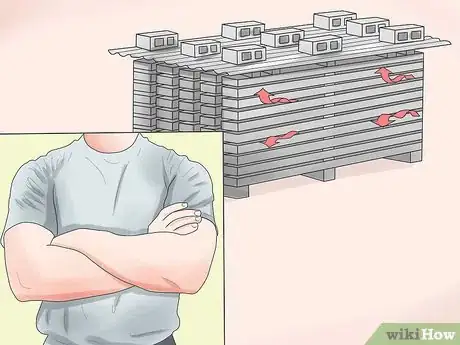

7Wait for the wood to dry. Drying times vary widely based on temperature, humidity, and ventilation conditions, but of course you can continually check the wood with your moisture meter to determine its readiness. A general rule is that a year of drying time will be needed for each inch (25 mm) of board thickness.[5]

Community Q&A

-

QuestionWhat is the minimum period for seasoning of freshly cut teak wood?

Community AnswerIn general, it depends on thickness and whether or not you are drying a log prior to cutting or slabs. Normally, it's one year plus if left in a somewhat regulated environment if a kiln is not used.

Community AnswerIn general, it depends on thickness and whether or not you are drying a log prior to cutting or slabs. Normally, it's one year plus if left in a somewhat regulated environment if a kiln is not used. -

QuestionWhere can I buy wood that has been pre-dried?

Community AnswerEverywhere. Wood being pre-dried or Kiln Dried is pretty much why you buy wood and don't just cut it off trees.

Community AnswerEverywhere. Wood being pre-dried or Kiln Dried is pretty much why you buy wood and don't just cut it off trees. -

QuestionIf I totally seal the wood before it dries completely, will it still shrink?

Community AnswerThe answer is no depending on what you seal it with, but in general, allowing wood to dry in the climate you live in (and to which it's exposed) is best. Unfortunately, that can take a long time, and it's absolutely best to seal the ends of the fresh cut cants or logs immediately to avoid splits as water will exit the ends faster (and unevenly). What you want is for the wood to lose its moisture through the surface, making sure all the bark is removed, it's in a dry place, and it's not subject to temperature extremes.

Community AnswerThe answer is no depending on what you seal it with, but in general, allowing wood to dry in the climate you live in (and to which it's exposed) is best. Unfortunately, that can take a long time, and it's absolutely best to seal the ends of the fresh cut cants or logs immediately to avoid splits as water will exit the ends faster (and unevenly). What you want is for the wood to lose its moisture through the surface, making sure all the bark is removed, it's in a dry place, and it's not subject to temperature extremes.

Warnings

- The traditional rule-of-thumb for air-drying lumber is to allow one year of drying time per inch of wood thickness to properly air-dry lumber. In situations where green wood is to be processed into usable boards, (especially in the case of thicker lumber), a kiln is frequently used to control the drying process. While there are various types of kilns used to dry lumber, the basic premise is usually the same: a large insulated chamber or room is used to balance and control humidity, temperature, and airflow to safely and efficiently bring wood down to an acceptable moisture content. But kiln drying may also introduce internal stresses into the wood—particularly if an improper kiln schedule is used, or if corrective measures are not employed—resulting in a condition known as case-hardening.⧼thumbs_response⧽

Things You'll Need

- Moisture meter

- Wood boards

- 1" x 2" (25 x 50 mm) boards

- Plywood

- Concrete blocks

- Box fan (optional)

References

- ↑ http://www.woodweb.com/knowledge_base/Woodworking_101_The_Basics.html

- ↑ https://www.wood-database.com/wood-articles/drying-wood-at-home/

- ↑ https://www.woodmagazine.com/materials-guide/lumber/how-to-succeed-at-air-drying-lumber

- ↑ https://www.woodmagazine.com/materials-guide/lumber/how-to-succeed-at-air-drying-lumber

- ↑ https://www.wood-database.com/wood-articles/drying-wood-at-home/

- http://www.youtube.com/watch?v=5sN4W_xGi7s

- http://www.woodweb.com/knowledge_base/Woodworking_101_The_Basics.html