This article was co-authored by wikiHow Staff. Our trained team of editors and researchers validate articles for accuracy and comprehensiveness. wikiHow's Content Management Team carefully monitors the work from our editorial staff to ensure that each article is backed by trusted research and meets our high quality standards.

There are 13 references cited in this article, which can be found at the bottom of the page.

This article has been viewed 14,892 times.

Learn more...

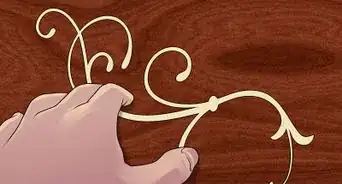

A sliding dovetail is a woodworking joint that allows you to slot together two separate pieces of wood without the need for screws, glue, or any other fasteners. It’s useful for lending simple elegance to drawers, shelves, and furniture. Despite their ornate appearance, dovetail joints are relatively easy to cut by hand, as long as you have the right tools. Our how-to guide will walk you through the simple steps of making your own sliding dovetail joint.

Steps

Setting up Your Materials

-

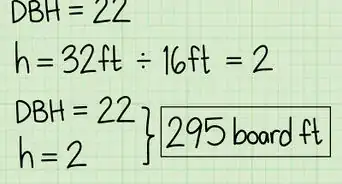

1Choose a joint size that works best for your project. It’s possible to make a sliding dovetail of just about any size, as long as your starting pieces are large enough. While the joint’s socket (the trench that the dovetailed piece will slide into) will almost always run the entire length of the piece it’s going in, the width of the groove is entirely up to you. As far as depth goes, a good general rule is to keep the socket between 1/3 and 2/3 of your wood’s total thickness.[1]

- Smaller joints can be useful for making multiple sturdy connections between two pieces, while larger joints tend to be more eye-catching and decorative. It’s mostly a matter of preference.[2]

- The strength of a dovetail joint has more to do with the quality of the wood you’re working with than size. Well-cut joints can hold up to years or even generations of use, even ones as shallow as 1⁄8 inch (0.32 cm).

-

2Mark the size and placement of your cut with a pencil. Once you’ve decided on a set of dimensions for your joint, draw two lines of a corresponding width down the face of your socket piece with the aid of a ruler or straightedge. These layout lines will be a big help when it comes time to set and guide your router, which you’ll be using to make the necessary cuts.[3]

- Typically, you’ll cut the socket into the broad side of one board and the dovetail into the end of the other. That way, you’ll be able to slot the two pieces together at a perpendicular angle.

Advertisement -

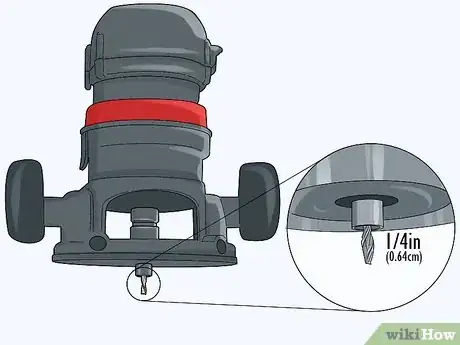

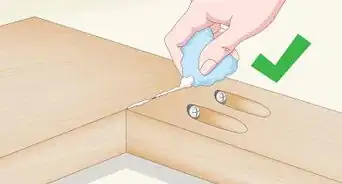

3Fit a router with a straight or spiral downcut bit of an appropriate size. Insert the slender end of the bit into the collet (the steel sleeve that holds the bit in place) on the tool’s circular base plate. Twist the locking nut on the collet clockwise by hand until it will no longer budge, then grab a wrench and tighten it down the rest of the way.[4]

- A 1⁄4 in (0.64 cm) bit will be ideal for routing standard 3⁄4 in (1.9 cm) stock boards and sheets.[5]

- A router is a woodworking tool designed to hollow out narrow sections along the surface of a piece of wood. Handheld routers are most common, but there are also router table setups that offer improved power and precision.

Tip: Try to select a bit wide enough to achieve a nice clean opening in a single pass. This will help to minimize errors and prevent you from having to go back and correct your mistakes later.

-

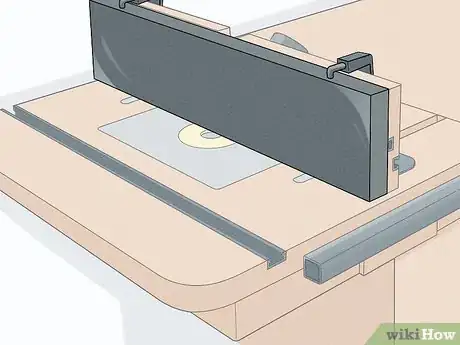

4Set up a fence or separate edge guide just outside your layout lines. Position the guide or fence so that your router’s bit sits squarely at the midpoint between the width lines you traced earlier. One of these tools will help to direct and stabilize your cuts.[6]

- Router tables come with their own adjustable fences for quick and easy setting. If you’re going to be using a handheld router, you’ll need to buy or rent a separate edge guide. You can pick up a basic edge guide from any hardware store or home improvement center for as little as $15-20.

- If you’re handy with a drill and tape measure, you can also try making your own pre-measured edge guide using a long piece of scrap wood, a cheap piano hinge, and a few wood screws.[7]

Routing the Socket

-

1Pull on a pair of earmuffs and some protective eyewear. Things are going to get pretty loud once you fire up your router. It’s also possible to send small shards of wood flying if you happen to slip or bear down too hard. The last thing you want is to take a splinter in the eye while you’re trying to delicately carve out the contours of your dovetail socket, or to end up temporarily deaf when you’re done![8]

- You might also choose to wear some rugged work gloves to keep your hands covered, though this could decrease the total amount of control your have over your piece or router a bit.

-

2Glide the router along the marked section of the wood. Now, switch on your router and set the base plate flush against both the piece and your edge guide or fence, with the bit itself positioned outside the edge of the wood. Move the router from left to right to ensure that it tracks smoothly and easily. If you’re using a router table, you’ll push your piece along instead while the stationary bit spins beneath it.[9]

- If you’re left-handed, it may feel more natural for you to move your materials from right to left.

- The purpose of this initial pass is just to remove as much excess wood, or “waste,” as possible before you come back to handle the detailed Hedgework.[10]

-

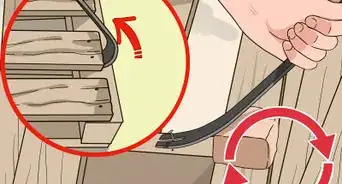

3Switch out your straight bit for a dovetail bit and repeat the process. Once again, move your router or piece along straight, making sure it stays in contact with the edge guide or fence at all times. The angled dovetail bit will shave off the bottom portion of the vertical edge made by your straight or spiral downcut bit to give the dovetail its signature tapered shape. You’re halfway done![11]

- Be sure to set your dovetail bit to a height that matches the intended depth of your socket. Most routers have a dial somewhere on the body of the tool that enables the user to change the height setting.

- If it’s your first time cutting a dovetail, you always have the option of backing off your edge guide or fence a bit and performing one or two light scoring cuts before you really dig in.[12]

-

4Rotate your piece 180 degrees and make a final pass to complete the socket. Turn your piece around (don’t flip it!) and reset your edge guide or fence as needed. Push the router along the wood or vice versa to carve a fanned dovetail into the other side of the groove. When you’re done, you’ll have a perfectly even angled socket to show for your efforts.[13]

- Work patiently and carefully. If you get in a rush, you could end up with unsightly tear out damage, which can both detract from the overall beauty of the finished joint and compromise the ability of the two pieces to fit together properly.[14]

- Always open up your socket first. It’s much easier to fit your tenon (the protruding section of the dovetail that actually slots into the groove) to your socket than the other way around.

Fashioning the Tenon

-

1Leave the dovetail bit in place on your router. You’ll be using the same bit to handle the detail work on your second piece. Sticking with the same bit will ensure that both pieces fit together like a glove.[15]

- Keep your bit set to the same height you settled on during the previous steps.

- While the socket for a sliding dovetail can easily be cut using a handheld router, a larger, more stable router table is generally better suited for machining the delicate dovetail tongues.[16]

-

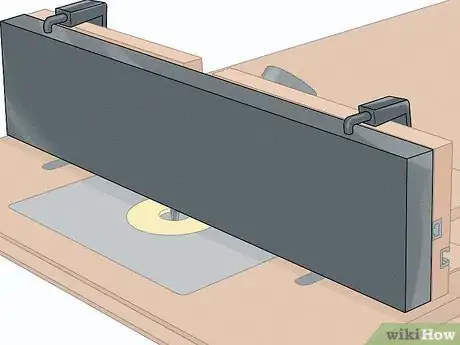

2Attach an auxiliary fence to your main router fence. The simplest way to do this is to shop around for a special premade auxiliary fence, though a sheet of perfectly flat scrap wood will also do the trick. Clamp the taller fence to your table’s existing fence on both ends using a pair of hand clamps. Doing so will extend its height, allowing it to support taller pieces.[17]

- Auxiliary fences are sold as add-on accessories for the standard-sized guide fences that router tables are equipped with. You can purchase one online or from any major home improvement center.

- After installing your auxiliary fence, adjust it so that only about 1⁄8 inch (0.32 cm) of the dovetail bit is visible beyond it.

- The average router table fence is only around 3–4 inches (7.6–10.2 cm) tall. Your auxiliary fence needs to be at least 5 inches (13 cm) tall in order to offer maximum security, precision, and ease of use.[18]

-

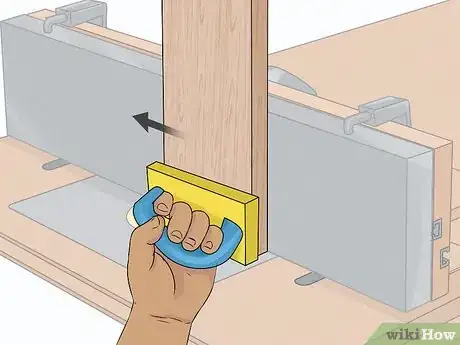

3Stand your piece up vertically on your work surface. Hold the piece in your dominant hand and use your opposite hand to pin it firmly against the table's fence. Double-check that the rear edge is flush with your fence and the bottom is flush with the table itself before you begin cutting.[19]

- You can also use a push block to keep your piece flat against the fence if you don’t feel comfortable holding it by hand.[20]

- You’re essentially doing the reverse of what you did to cut the socket—since the wood was lying flat for that piece, it needs to be upright here.

-

4Guide the rear edge of your piece along the fence to start your first set of cuts. Push the wood away from you slowly and fluidly while at the same time pressing it into the fence. As you do, the whirling bit will plane the vertical surface of the wood to an angle that complements those on the inside of the socket you cut earlier.[21]

- Place a scrap “backer board” behind the piece you’re working on to help keep it moving and avoid tear out.[22]

-

5Rotate your piece 180 degrees and make an identical cut on the other side. Everytime you go over the router with one side of your piece, make sure you turn it around and do the same for the opposite side. This will guarantee that the finished dovetail is nice and symmetrical, and that the resulting joint is as tight-fitting and as strong as possible.[23]

- Take a moment to pause and test your fit with your socket after each pair of passes.

-

6Continue shaving down both sides of the tenon until it's just the right size. Adjust the fence so that a little more of the bit is exposed, then reset your piece and proceed with your second set of cuts. The idea is to “start fat and finish lean.” In other words, gradually removing the material on both sides of your piece until you end up with a tail that's exactly the same width and depth as your socket.[24]

- Be careful to shift the fence back by half of the total amount of width you want to take off. However much wood you decide to remove from one side of your piece, that amount will actually be double, since you’ll be repeating the process on the opposite side.[25]

- If you discover that your tenon is only a hint too big to fit the socket, another clever solution is to lightly sand it with a sheet of medium-grit sandpaper until it slips right in.

Tip: If you’re going to be fashioning multiple joints, leave your fence in the “sweet spot” once you find it to make your future cuts faster and more efficiently.

-

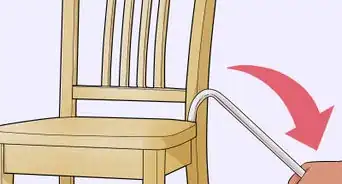

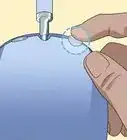

7Slide the completed dovetail into the socket to assemble the joint. Line up one of the outer edges of your dovetailed piece with one of the ends of your socket. You should be able to coax the piece in using a small amount of hand pressure or a few light taps with a rubber mallet, assuming you sized and cut both pieces correctly. That’s all there is to it![26]

- If you like, you apply a small amount of wood glue to one or both pieces to strengthen the joint. Keep in mind, though, that this will make it impossible to separate the two pieces later.

Warnings

- Routers make use of sharp pieces of metal rotating at high speeds. For this reason, it’s important to follow the basic safety precautions that you would when working with saws, drills, and other potentially-dangerous high-powered tools.[27]⧼thumbs_response⧽

Things You’ll Need

Setting up Your Materials

- Edge guide or adjustable guide fence

- Straight or spiral downcut bit

- Dovetail bit

- Pencil

- Ruler or straight edge

- Earmuffs

- Safety glasses or goggles

- Protective gloves (optional)

Routing the Socket

- Handheld router or table router

- Wooden boards or sheets

Fashioning the Tenon

- Wooden boards or sheets

- Handheld router or table router

- Edge guide or adjustable guide fence

- Dovetail bit

- Auxiliary fence or scrap sheet of wood

- Hand clamps

- Push block (optional)

- Scrap board (optional)

- Medium-grit sandpaper (optional)

References

- ↑ https://www.canadianwoodworking.com/tipstechniques/sliding-dovetails

- ↑ https://www.youtube.com/watch?v=C2M1s5q5D_0&feature=youtu.be&t=80

- ↑ https://www.woodmagazine.com/woodworking-tips/techniques/routing/slidingdovetails

- ↑ https://www.youtube.com/watch?v=8Vl8Jbw3cSk&feature=youtu.be&t=219

- ↑ https://www.woodmagazine.com/woodworking-tips/techniques/routing/slidingdovetails

- ↑ https://www.popularwoodworking.com/techniques/how-to-make-a-sliding-dovetail/

- ↑ https://www.3x3custom.com/tutorials/easy-diy-router-edge-guide

- ↑ https://www.finewoodworking.com/2009/01/25/how-to-cut-sliding-dovetail-joints

- ↑ https://www.youtube.com/watch?v=C2M1s5q5D_0&feature=youtu.be&t=255

- ↑ https://www.finewoodworking.com/2009/01/25/how-to-cut-sliding-dovetail-joints

- ↑ https://www.finewoodworking.com/2009/01/25/how-to-cut-sliding-dovetail-joints

- ↑ https://www.popularwoodworking.com/techniques/how-to-make-a-sliding-dovetail/

- ↑ https://www.canadianwoodworking.com/tipstechniques/sliding-dovetails

- ↑ https://www.popularwoodworking.com/techniques/how-to-make-a-sliding-dovetail/

- ↑ https://www.finewoodworking.com/2009/01/25/how-to-cut-sliding-dovetail-joints

- ↑ https://www.youtube.com/watch?v=C2M1s5q5D_0&feature=youtu.be&t=293

- ↑ https://www.woodmagazine.com/wood-routers/lengthy-auxiliary-fence-extends-router-table-range

- ↑ https://www.canadianwoodworking.com/tipstechniques/sliding-dovetails

- ↑ https://www.canadianwoodworking.com/tipstechniques/sliding-dovetails

- ↑ https://www.youtube.com/watch?v=C2M1s5q5D_0&feature=youtu.be&t=338

- ↑ https://www.popularwoodworking.com/techniques/how-to-make-a-sliding-dovetail/

- ↑ https://www.woodmagazine.com/woodworking-tips/techniques/routing/slidingdovetails

- ↑ https://www.youtube.com/watch?v=C2M1s5q5D_0&feature=youtu.be&t=324

- ↑ https://www.popularwoodworking.com/techniques/how-to-make-a-sliding-dovetail/

- ↑ https://www.canadianwoodworking.com/tipstechniques/sliding-dovetails

- ↑ https://www.woodmagazine.com/woodworking-tips/techniques/routing/slidingdovetails

- ↑ https://ohsonline.com/articles/2010/03/19/power-tool-safety-tips-from-osha.aspx