wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 17 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 94% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 83,722 times.

Learn more...

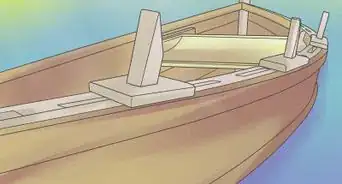

Any reasonably handy boat owner can caulk their own boat, there is no magic involved. On a new boat, with pristine seams between the planks, it is pretty straight forward. On an older boat the seams may be damaged and vary in width so, a little more care is needed. However, anyone with a modicum of commonsense will have no trouble doing a competent job. The main thing to be aware of is, not to over caulk, this could lead to strained frames as the planking ‘takes up’.

Steps

Preparation

-

1Get the boat ready for caulking. If you intend to repaint your boat, strip off the paint before starting to re-caulk.

-

2Clean out all the old putty and caulking cotton with the raking iron, taking care not to damage the wood.Advertisement

-

3Prime the seams with the oil based paint or with red-lead paint.

Paying the cotton

-

1Different builders have differing ideas on where to start caulking.

-

2Some like to do all the butt ends first then start on the lower seams and finish off with the rabbet and garboard seam.

-

3However, here is no reason why you should not start on a seam above the water line, if you want to get into the swing of it first.

-

4The main thing is remembering which seams have been done and which are still to do.

-

5How many strands of cotton you use will depend on the size of the seams.

-

6Ideally the cotton should fill the deepest third of the seam.

-

7This means that when tapping it home the iron should go in by about two thirds of the plank thickness.

-

8Add or subtract strands as needed.

-

9But always remember that it is to be tapped in not hammered.

-

10Don’t over caulk, the cotton and the wood are going to swell when wet.

-

11Some authorities suggest laying out enough cotton to do a full seam.

-

12That is fine if you are laying it out in a perfectly clean floor.

-

13The cotton is rather hairy and will pick up any and every bit of dirt or wood shaving on the floor.

-

14I found that it was better to feed it straight from the ball, but keeping the ball in a cardboard box which can be pushed along with your foot as you go.

-

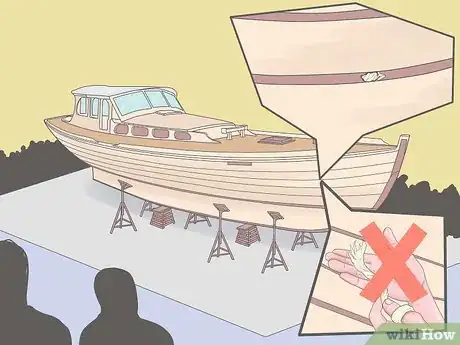

15If you have to join strands mid seam do not tie a knot, this will produce a thick, hard lump.

-

16Simply roll the ends together between finger and thumb.

-

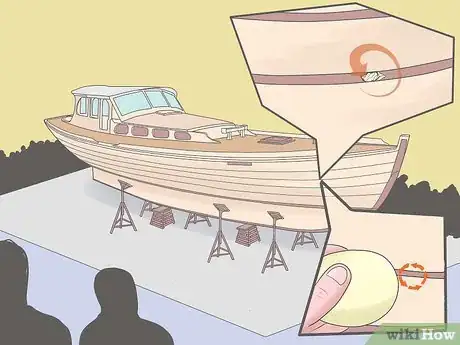

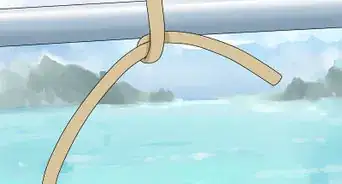

17Start off by using the paying iron to tack or loop the cotton loosely into a foot or two of the seam.

-

18Then go back and using a rocking action with the iron tap the cotton home with the mallet.

-

19If there are any wide seams leave them for last.

-

20By caulking all the tight seams first you could find that this has caused the wider ones to close up.

-

21Wide seams can be caulked in two runs, thus increasing the number of strands.

-

22Some builders suggest priming the cotton before applying the putty.

Mixing the Putty

-

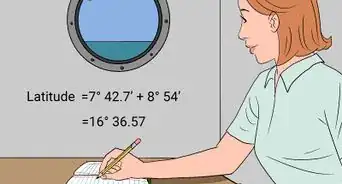

1The traditional compound for stopping seams is linseed oil putty mixed with red led powder.

-

2When mixing this caulking compound take a tennis ball sized dollop of the putty mix enough red lead powder to give an even red color add linseed oil if needed to keep it soft.

-

3Then add a thumbnail sized dollop of multi-purpose grease, mix it well and push it into the seam with a putty knife.

-

4The grease will help keep the putty soft and flexible thus preventing any hardening and cracking later.

-

5You can either smooth the putty flush with the planking or used a curved scraper to produce a concave seam.

Launch day

-

1When it comes to launch day you might find that some of the seams have opened up.

-

2Do not be tempted to add any more caulking cotton.

-

3You can add some more of the paying compound but this will probably end up being squeezes out as the wood and cotton take up.

-

4Providing the gaps are not excessive its better to use a temporary method of stopping.

-

5Taping over the cracks with masking tape will slow water intake sufficiently while the planks take up.

-

6Or fill the cracks with soap, use bar soap rubbed into the crevices this will eventually just wash away.

-

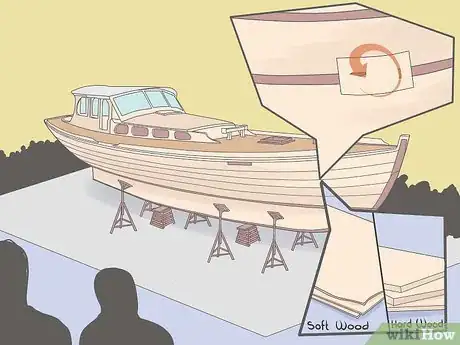

7How quickly she takes up will depend on the wood of the planking.

-

8Soft woods will usually take up faster than hardwood.

-

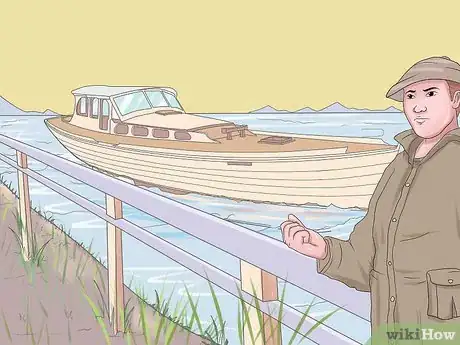

9My first attempt at re-caulking a complete hull was on Mignonne, she has been in the water now for three years and she is still afloat and watertight.

-

10If I can do it anyone can, with a little care you can do it too.

Things You'll Need

- 2 caulking irons.

- paying iron, narrow enough to penetrate two thirds of the depth of the seam without damaging the wood.

- nib iron, this is a smaller iron for caulking short seams such as ‘nib-ends’.

- raking iron, to clean out the old caulking compound and the old cotton.

- caulking mallet/wooden carpenters mallet.

- putty knife or similar for mixing and applying the caulking compound.

- Some oil based paint for priming the seams.

- Caulking Cotton. Oakum, which is made from hemp soaked in pine tar, is normally only used on the larger vessels with planks over two inches thick.

- Linseed oil putty.

- Red lead powder.

- Grease, any ordinary car type grease will do.

- Linseed oil.

References

- How to Caulk a Carvel Hull - Original source of this page. Shared with permission