X

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 12 people, some anonymous, worked to edit and improve it over time.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 89% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 90,267 times.

Learn more...

Working as a shelf stocker? Turn those pallets in the back room into well-stocked shelves efficiently.

Steps

-

1When the pallet comes in, break it down onto separate pallets or carts depending on the size of the freight. Be sure to organize each cart by aisle or product for maximum efficiency when you actually go out to stock it.[1]

-

2Take the carts and pallets to the correct aisles. Make sure to leave a lot of breathing room for customers if you are working during opening hours![2]Advertisement

-

3Locate where the items go. Items on the carts and pallets should be properly assigned to the aisle you're working in. Most stores should supply electronic devices (known here as Geminis or telezons/telxons/telxons) that let you scan items and find where they go on the shelves. Boxes also sometimes have stickers on them that might say the aisle number (found on the bottom of the lowest shelf, normally on a corner, a small sticker that's usually a letter and a number if you're in a big grocery store, ie; A-13 ) One of the fastest ways you can locate items is by type and brand, it takes a while to get an eye for it but it's crucial if you don't have price guns.[3]

-

4Stock the items. Obviously the most important task! First of all, check how much stock is on the shelf. Push it back to see how much room you have, move stuff around if need be. Freight boxes should ALWAYS say how many items are in it. ( 12 - 5oz bottles, etc) Count carefully. Try your best to avoid "partials" which is only putting half of the items up and sending the rest back, unless your store allows that. If you're working in dairy or with other quick perishables, always check the date on the item before you stock new freight. Some boxes will say "rotate", this means to put stuff with the closest expiration date in front of the stuff with the farthest date. If you are stocking a shelf with one or two things left over, it's sometimes okay to stack them on top of the other items if you have room - or even sneak it behind something else on a shelf.[4]

-

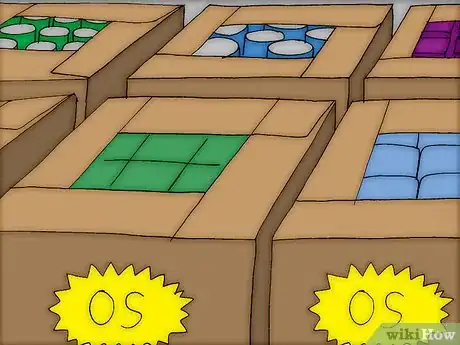

5When finished stocking, return to the back room and repeat until all of the pallets are done. Any and all overstock needs to be dated with the expiration date or marked with an "OS" for overstock. Properly label your stock for people working in the back room. Learn how to tag stuff for them to make their lives easier, they will greatly appreciate it.

-

6Zone your aisle. Zoning is front facing all the labels, checking the shelves for broken or stolen merchandise hiding behind other items, and just fixing things up and making it look pretty.

Advertisement

Community Q&A

-

QuestionHow do I keep rows of canned goods straight?

Community AnswerThere's nothing you can do but continually straighten them as people move them around.

Community AnswerThere's nothing you can do but continually straighten them as people move them around. -

QuestionShould I downstack all the pallets or work one at a time?

Community AnswerIt's entirely up to you. Whichever is more convenient for you is what you should do, unless your supervisor says otherwise.

Community AnswerIt's entirely up to you. Whichever is more convenient for you is what you should do, unless your supervisor says otherwise. -

QuestionWhat are the usual hours people stock shelves at clubs?

Community AnswerStocking normally takes place late at night or early in the morning to minimize the inconvenience for customers.

Community AnswerStocking normally takes place late at night or early in the morning to minimize the inconvenience for customers.

Advertisement

References

About This Article

Advertisement

-in-US-Step-10-Version-2.webp)