Productivity Improving Technologies

Productivity improving technologies are technologies that lower the traditional factors of production of land, labor capital, materials, and energy that go into production of economic output. Increases in productivity are responsible for increases in per capita living standards. Since the beginning of the Industrial Revolution, some major contributors to productivity have been:

- The spinning jenny and spinning mule greatly increased the productivity of thread manufacturing compared to the spinning wheel.

- Replacing human and animal power with water power, wind power, steam, electricity, and internal combustion greatly increased the use of energy.

- Energy efficiency in the conversion of energy to useful work.

- Infrastructures: canals, railroads, highways, and pipelines.

- Mechanization of both production machinery and agricultural machines.

- Work practices and processes: the American system of manufacturing, Taylorism or scientific management, mass production, assembly line, modern business enterprise.

- Materials handling: bulk materials, palletization, and containerization.

- Scientific agriculture: fertilizers and the green revolution, livestock and poultry management.

- New materials, new processes for production and dematerialization.

- Communications: telegraph, telephone, radio, satellites, fiber optic network, and the Internet.

- Home economics: public water supply, household gas, appliances.

- Automation and process control.

- Computers and software, data processing.

Productivity gains were not just the result of inventions, but also of continuous improvements to those inventions which greatly increased output in relation to both capital and labor compared to the original inventions. Productivity also arises from developing economies of scale, despite that not actually being a technology in its own right.

Industrial Machinery

The most important mechanical devices before the Industrial Revolution were water and windmills. Just before the Industrial Revolution, water power was applied to bellows for iron smelting. Wind and water power were also used in sawmills. The technology of building mills and mechanical clocks was important to the development of the machines of the Industrial Revolution.

The spinning wheel was a medieval invention that increased thread making productivity by a factor greater than ten. Later in the Industrial Revolution came the flying shuttle, a simple device that doubled the productivity of weaving. Spinning thread had been a limiting factor in cloth making, requiring 10 spinners using the spinning wheel to supply one weaver. With the spinning jenny, a spinner could spin eight threads at once. The spinning mule allowed a large number of threads to be spun by a single machine using water power. A change in consumer preference for cotton at the time of increased cloth production resulted in the invention of the cotton gin. Steam power eventually was used as a supplement to water during the Industrial Revolution, and both were used until electrification.

Machine Tools

Machine tools, which cut, grind, and shape metal parts, were another important mechanical innovation of the Industrial Revolution. Before machine tools, it was prohibitively expensive to make precision parts, an essential requirement for many machines and interchangeable parts. Perhaps the best early example of a productivity increase by machine tools and special purpose machines is the Portsmouth Block Mills. With these machines, 10 men could produce as many blocks as 110 skilled craftsmen.

Historically important machine tools are the screw-cutting lathe, milling machine, and metal planer (metalworking), which all came into use between 1800 and 1840. However, around 1900, it was the combination of small electric motors, specialty steels, and new cutting and grinding materials that allowed machine tools to mass produce steel parts.

Productivity Gains From Computer Hardware

Computer hardware is the collection of physical elements that comprise a computer system. Computer hardware refers to the physical parts or components of computer (objects you can touch), such as a:

- Monitor;

- Keyboard;

- Printer;

- Chip;

- Hard disk; and

- Mouse.

The history of computing hardware is the record of the ongoing effort to make hardware faster, cheaper, and capable of storing more data.

The Rapid Increase in Productivity

Early electric data processing was done by running punched cards through tabulating machines, the holes in the cards allowing electrical contact to incremental electronic counters. Tabulating machines were in a category called "unit record equipment," through which the flow of punched cards was arranged in a program-like sequence to allow sophisticated data processing. They were widely used before the introduction of computers.

The first digital computers were more productive than tabulating machines, but not by a great amount. Early computers used thousands of vacuum tubes (thermionic valves), which used a lot of electricity and constantly needed replacing. By the 1950s, the vacuum tubes were replaced by transistors which were much more reliable and used relatively little electricity. By the 1960s, thousands of transistors and other electronic components were being manufactured on silicon semiconductor wafers as integrated circuits, which are universally used in today's computers.

In 1973, IBM introduced point of sale (POS) terminals in which electronic cash registers were networked to the store's mainframe computer. By the 1980s, bar code readers were added. These technologies automated inventory management. The Bureau of Labor Statistics estimated that bar code scanners at checkout increased ringing speed by 30% and reduced the labor requirements of cashiers and baggers by 10-15%.

Computers did not revolutionize manufacturing because automation, in the form of control systems, had already been in existence for decades. Although they did allow more sophisticated control, which led to improved product quality and process optimization. Today's servers and mainframes are capable of processing enormous amounts of data. Moreover, this type of processing power has become much easier to obtain through cloud computing services .

Intel CPU

Hardware advancements, such as the CPU, greatly increased productivity for many areas of society.

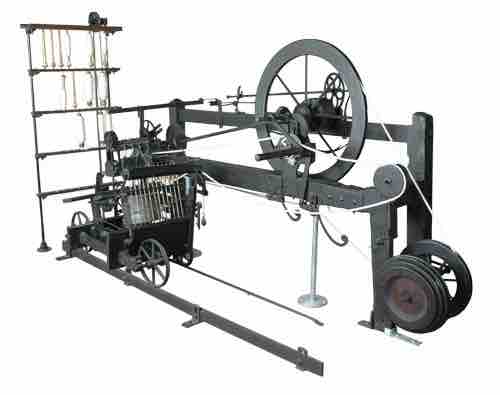

Productivity Technology

The introduction of the spinning mule into cotton production processes helped to drastically increase industry consumption of cotton. This example is the only one in existence made by the inventor Samuel Crompton. It can be found in the collection of Bolton Museum and Archive Service.