wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 16 people, some anonymous, worked to edit and improve it over time.

This article has been viewed 54,299 times.

Learn more...

Anhydrous ammonia, as its name suggests, is ammonia kept separate from water. With molecules consisting of 1 atom of nitrogen to 3 atoms of hydrogen, anhydrous ammonia is used as an agricultural fertilizer to recharge the soil with nitrogen depleted by crops, as well as a desiccant to slow mold growth in high-moisture grains and a protein enriched of corn silage. However, its chemical properties make it a dangerous chemical to work with, requiring proper safeguards for storage, use and transport.

Steps

Storing Anhydrous Ammonia

-

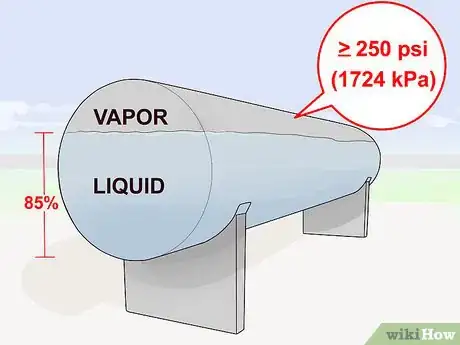

1Store anhydrous ammonia under pressure. Anhydrous ammonia boils at a temperature of -28 degrees Fahrenheit (-33 degrees Celsius). To keep it liquid at temperatures above this, it must be stored and injected into the soil under pressure. (Once in the soil, the liquid ammonia turns to gas, releasing its nitrogen into the soil as it absorbs the soil's moisture.) Containers used to store anhydrous ammonia should conform to the guidelines of the American National Standards Unit, with all parts and surfaces able to withstand a pressure of at least 250 pounds per square inch (1724 kilo-pascals).

- One cubic foot (28.3 liters) of liquid anhydrous ammonia vaporizes to 855 cubic feet (24,196.5 liters) of gas. Nurse tanks (on-farm storage tanks) and applicator tanks should be filled no more than 85 percent full, to allow for some of the ammonia to vaporize without rupturing the tank.

-

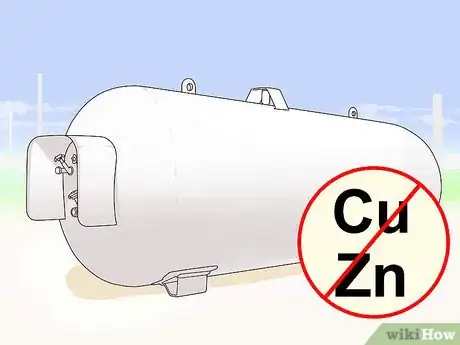

2Use only non-corrosive storage containers. Anhydrous ammonia will corrode metals such as copper and zinc and any alloys that include those metals. Because zinc is used to galvanize steel, galvanized steel containers and pipe cannot be used with anhydrous ammonia.Advertisement

-

3Paint tanks in light, reflective colors such as white or silver. This will reflect heat, helping to keep the tanks cooler and the pressure inside them lower. Label nurse tanks with "ANHYDROUS AMMONIA" in letters that are 4-inches (10-centimeters) high on the sides and rear of the tank, with the words "INHALATION HAZARD" in letters 3-inches (7.5-centimeters) high on either side.

-

4Inspect all storage tanks and hoses on a regular basis and service them as needed. Walk around the tanks looking for defects; you can get a checklist of what to look for from your supplier. Inspect the hoses for bulges, blisters, cracks or cuts, and replace them if you see any slippage around the coupling.

- Hoses designed for anhydrous ammonia use should have the words "ANHYDROUS AMMONIA" stamped on them, as well as the maximum rated pressure, the manufacturer's name and dates of manufacture and expiration. Nylon-reinforced hoses should be replaced every 4 years and stainless-steel-reinforced hoses every 6 years, sooner if defects are found.

- The pressure relief valve should be replaced every 5 years, sooner if leaks or other defects are found.

- Leaks can easily be detected; anhydrous ammonia has a distinct odor easily detectable at 50 parts per million (ppm), enough to drive someone away. A concentration of 134 ppm irritates the nose and throat, while a concentration of 700 ppm leads to coughing and severe eye irritation. Concentrations of over 1,700 ppm lead to serious injury and death, while a concentration 5,000 ppm will asphyxiate someone within minutes.

-

5Keep protective gear on hand if you store anhydrous ammonia in bulk. You'll need a raincoat and least 2 gas masks with current air canisters. The gas masks will only protect you against low concentrations of ammonia gas; if a major leak occurs, contact your local fire department, which has the training and equipment to deal with a serious leak.

Handling Anhydrous Ammonia

-

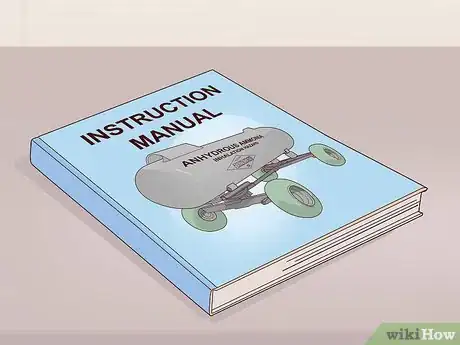

1Read and follow the instructions that come with your equipment. Be sure all farm workers who will work with anhydrous ammonia are familiar with these procedures and refer any questions to your farm equipment dealer.

- U.S. federal law requires anyone working with anhydrous ammonia to be at least 16 years of age.

-

2Wear protective gear. To protect yourself, wear a heavy-duty, long-sleeved shirt and long pants and/or coveralls, along with rubber gloves with an extended cuff that can be turned down to catch any of the liquid ammonia if it runs down your arms when they're raised. Cover your face with either chemical-proof goggles or a full-face respirator.

- Regular glasses are not a substitute for goggles, but if you wear normally wear contact lenses, wear your glasses under your goggles instead of your contacts when working with anhydrous ammonia. That way, should any ammonia seep into your eyes, you can flush them with water; contact lenses will trap the ammonia and damage your eyes before you can remove them.

-

3Keep clean water on hand. Many states require that a 5-gallon (19-liter) tank of water be kept near nurse and applicator tanks of anhydrous ammonia to flush the eyes and wash the skin if either comes in contact with the ammonia. It's also a good idea to have a second such water tank on the tractor itself, and handlers should also carry an 8-ounce (237-milliliter) water bottle on their person at all times while around anhydrous ammonia. Water in tanks should be changed daily to ensure its cleanliness.

- The water is necessary because anhydrous ammonia has a strong affinity for water. In liquid form, it will first freeze the skin, then cause rapid dehydration and severe chemical burns as it pulls moisture out of the body.

-

4Transfer ammonia between tanks in a safe manner. The nurse tank should be parked close to the source tank, on level ground and downwind of the source tank, away from obstacles. Block the wheels of the wagon carrying the nurse tank and set the towing vehicle's parking brake. Inspect the filler hose couplings and connectors for dirt or damage before connecting the hoses, and carry the hose by the valve body or coupling, not the flow control wheel. Always turn the flow control wheel by hand, to avoid damaging its fitting and causing a leak.

- If transferring ammonia between tanks with a compressor, keep the pressure in the receiving tank lower than that of the source tank to avoid backflow. As noted previously, the receiving tank should be filled no more than 85 percent full.

-

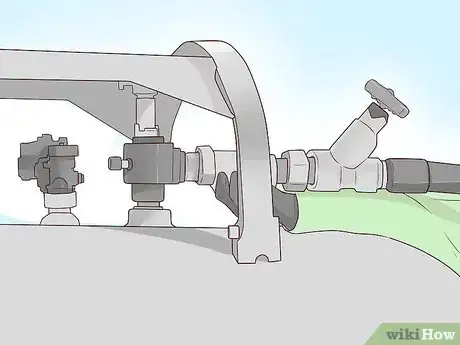

5Maintain safety precautions when applying anhydrous ammonia. The hose between the nurse or applicator tank and the applicator tool bar should have a breakaway coupler kept in good working condition to cut off the ammonia flow if the applicator separates from the tank. When unclogging applicator tubes, stand upwind from the tubes wearing your protective clothing and use a long piece of heavy-gauge wire to remove the debris.

- If the coupler separates, vent off the pressure in the lines attached to the tank and applicator with the bleeder valves before reconnecting. You may also want to bleed the lines before unclogging the applicator tubes to prevent the ammonia from rushing out through the opened holes.

Transporting Anhydrous Ammonia

-

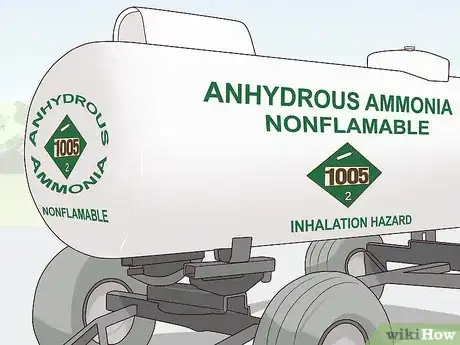

1Label the transport tank. The words "ANHYDROUS AMMONIA" and "NONFLAMMABLE" need to appear in large green letters on both sides and either end of the tank, along with U.S. Department of Transportation placards showing the code number "1005" alongside those words. The words "INHALATION HAZARD" need to appear on 2 of the 4 sides.

- Many states regard farmers' transport tanks as "implements of husbandry." As such, they must comply with the state's regulations for such implements, in addition to federal regulations.

-

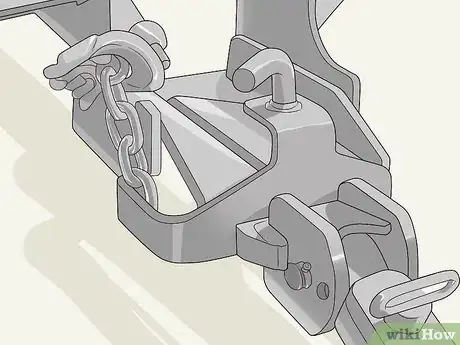

2Attach the tank wagon to the towing vehicle securely. You'll need a drawbar, hitch pin, safety clip and safety chains, which should be secured and inspected each time you set out on the highway, as should the wagon's tires and wheel lug nuts. An improperly secured tank wagon may fishtail from side to side, which could cause it to overturn or collide with another vehicle.

-

3Tow the tank as a slow-moving vehicle. Slow-moving vehicles can travel no faster than 25 miles per hour (40 kilometers per hour), and must display a slow-moving vehicle emblem at the rear.

- Individual states may have additional requirements for tank wagons being towed at night to display lights and reflectors to be better seen by oncoming vehicles.

Community Q&A

-

QuestionWhat kind of transfer pump is needed?

Roblox NoobCommunity AnswerMost fuel transfer pumps handle gasoline, diesel, ethanol and kerosene. However, other pumps are designed for lubricants and high-viscosity fluids like motor oil, transmission fluid and antifreeze. Make sure the pump you select matches the fluid you need to transfer.

Roblox NoobCommunity AnswerMost fuel transfer pumps handle gasoline, diesel, ethanol and kerosene. However, other pumps are designed for lubricants and high-viscosity fluids like motor oil, transmission fluid and antifreeze. Make sure the pump you select matches the fluid you need to transfer. -

QuestionWhat kind of piping is used for moving ammonia through the plant?

Roblox NoobCommunity AnswerWhenever working with ammonia refrigeration units, it is important to remember that ammonia can be corrosive to certain types of metals; it requires specially-rated piping. Copper piping, for example, which is commonly used in other types of refrigeration units, cannot be used when working with ammonia.

Roblox NoobCommunity AnswerWhenever working with ammonia refrigeration units, it is important to remember that ammonia can be corrosive to certain types of metals; it requires specially-rated piping. Copper piping, for example, which is commonly used in other types of refrigeration units, cannot be used when working with ammonia. -

QuestionHow do I apply anhydrous ammonia?

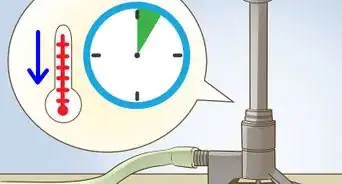

Roblox NoobCommunity AnswerOn silt loam or heavier-textured soils, wait to apply anhydrous ammonia until soil temperatures at the 4-inch depth are below 50 degrees F (in most years, this will be in November). Use a nitrification inhibitor such as N-Serve with anhydrous ammonia to help reduce fall nitrification rates.

Roblox NoobCommunity AnswerOn silt loam or heavier-textured soils, wait to apply anhydrous ammonia until soil temperatures at the 4-inch depth are below 50 degrees F (in most years, this will be in November). Use a nitrification inhibitor such as N-Serve with anhydrous ammonia to help reduce fall nitrification rates.

Warnings

- Anyone who has inhaled ammonia needs to be moved to a safe area. If the person is coughing convulsively, take him or her to a doctor or hospital. If the person stops breathing, administer CPR and get emergency medical assistance.⧼thumbs_response⧽

- If someone swallows ammonia, contact a doctor at once. If the person is still conscious and not in shock, have him or her drink plenty of water to dilute the ammonia. If the person vomits, keep the head below the hips to keep the vomit from entering the lungs. Do not induce vomiting or give fluids to someone in shock or unconscious.⧼thumbs_response⧽

- Although ammonia will not ignite at temperatures below 1560 degrees Fahrenheit (849 degrees Celsius), decontaminate any anhydrous ammonia container or piping before attempting to weld it, and never attempt to weld a closed container.⧼thumbs_response⧽

- Anyone whose skin is exposed to anhydrous ammonia should be removed to a safe area immediately. The affected area should be flushed with water for at least 15 minutes, the contaminated clothing removed as soon as possible, and the person taken to a doctor or hospital. (If the eyes are affected, hold them open while flushing to prevent the eyelids from trapping any of the ammonia.) Do not apply any kind of salve or ointment, as it may seal any ammonia residue into the skin and cause further damage.⧼thumbs_response⧽

- Never pour ammonia into an aluminum container. It will create a dangerous chemical reaction.⧼thumbs_response⧽