This article was co-authored by Gerber Ortiz-Vega. Gerber Ortiz-Vega is a Masonry Specialist and the Founder of GO Masonry LLC, a masonry company based in Northern Virginia. Gerber specializes in providing brick and stone laying services, concrete installations, and masonry repairs. Gerber has over four years of experience running GO Masonry and over ten years of general masonry work experience. He earned a BA in Marketing from the University of Mary Washington in 2017.

wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 100% of readers who voted found the article helpful, earning it our reader-approved status.

This article has been viewed 78,975 times.

Cement board is a strong and durable material that is great for projects like tiling, flooring, and countertops. It is inexpensive, convenient, and is long-lasting because the cement doesn’t rot like other materials. Cutting cement board to size is simple if you have the right tools, take the proper precautions, and follow the right procedures.

Steps

Scoring and Snapping Thin Cement Board

-

1Lay the cement board flat. For thin sheets of cement board, scoring the sheet and then snapping it is an easy and effective way to cut the material. Decide which side of the board is the “good” side, the side that will be facing up when you install the board, and lay the board on the ground, a sawhorse, or a workstation with the good side facing up. Be sure to clear the area of anything that could mark or damage the board.[1]

- The cement board needs to be between 1⁄4 inch (0.64 cm) and 1⁄2 inch (1.3 cm) in thickness in order to be scored and snapped. Any thicker and you’ll have to use a saw to cut it.

-

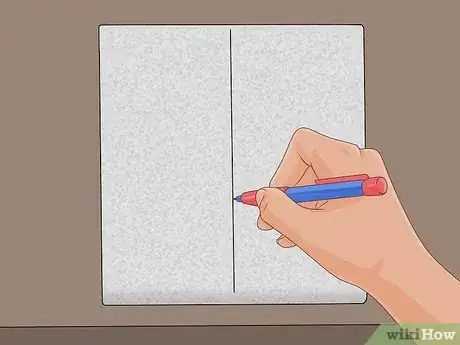

2Draw a line with a carpenter’s pencil where you want to cut the board. With the cement board flat, use a ruler to guide your pencil as you mark a line where you want to cut the board. Make sure the line is straight and visible. You may need to trace over the line a few times to leave a mark that you can see well.[2]

Tip: You can use a straight edge or any other object with a straight line like a book, board, or a box to guide your pencil.

Advertisement -

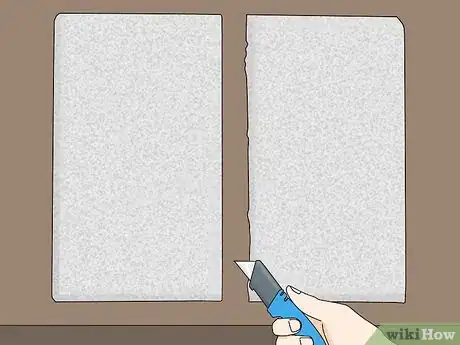

3Use a utility knife to cut along the line you marked on the board. Make sure the board is flat and stable and isn’t wobbly or uneven. Apply pressure and use a ruler to guide your utility knife as you drag it across the line you marked to score the cement board. Repeat the cuts 2 or 3 times, applying more pressure each time to make the cuts deeper and deeper until the cut penetrates about halfway through the board.[3]

- If you have a scoring tool, you can use that to make your cuts.

- The deeper you can make your cuts, the easier it will be to snap the board.

-

4Split the board with your knee. After you’ve scored the cement board deeply, stand it up from where you’ve had it laid flat. Place your knee on the backside of the board level with where you made your cuts. Apply pressure with the weight of your knee as you hold the board to split it along the lines you scored into the board.[4]

- If the board is not splitting easily, you may need to make your cuts deeper first.

-

5Cut the inner mesh with your utility knife. When the board splits, there may be some wire or fiberglass mesh keeping it together. Use your utility knife to cut the mesh. If you’re holding the board to cut the mesh, make sure it doesn’t drop on the ground as it may chip or crack.[5]

- Make sure to cut in a direction away from you!

Cutting Straight Lines with a Circular Saw

-

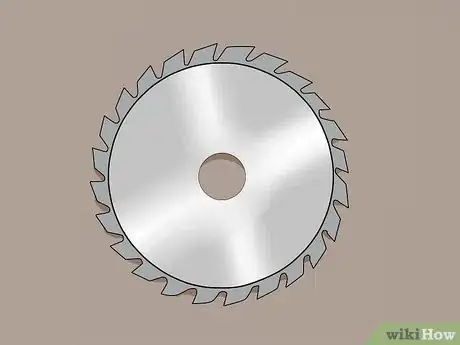

1Use a carbide-tipped wood-cutting blade to minimize dust. Cement is a very hard material, so you’ll need to use a blade that can handle the material. Carbide-tipped wood-cutting blades have fewer teeth than other circular saw blades and the carbide can withstand the strain of the cement. Choose the blade that has the least number of teeth.

- The smaller number of teeth on the blade will minimize the amount of concrete dust that is released from cutting the board.[6]

Warning: Concrete dust is hazardous if you breathe it in or get it in your eyes. Wear eye protection and breathing protection when you saw your cement boards.[7]

-

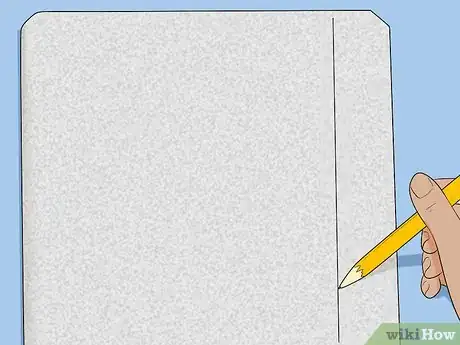

2Mark a straight line with a carpenter’s pencil where you want to cut. Use a straight edge or a ruler to mark a straight line on the cement board. This line will be your guide as you saw the board with the blade of the circular saw, so make sure it is straight and visible. You will be cutting along the backside of the board, so put your pencil mark on the underside of the cement board so it will be visible when you cut it with the saw.[8]

- Use a carpenter’s pencil because a regular pencil will dull after a few lines on cement.

-

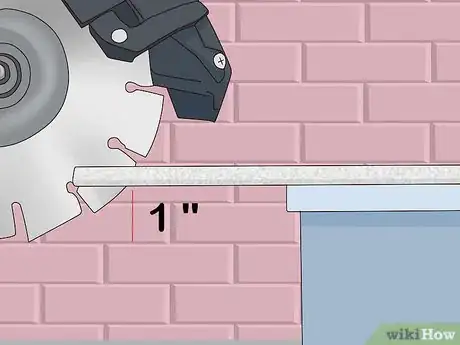

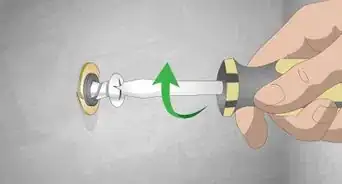

3Set the depth of the blade to extend 1⁄2 inch (1.3 cm) below the board. Unplug the circular saw and hold it next to the cement board with the blade guard retracted. Loosen the knob that allows you to adjust the depth and pivot the saw’s base until it extends past the bottom of the cement board. Then tighten the knob and make sure the blade is secure.[9]

-

4Set the board front-side down and align the cutting guide of the saw. The blade of the circular saw cuts from the lower side and into the board, so place the backside of the board facing up so the front will have a smoother edge. Place the board face-down on a sawhorse and place the front of the saw base on the workpiece to align the cutting guide with the line you marked on the board.[10]

- Make sure the board is secure and doesn’t shake or move.

-

5Bring the saw to full speed before cutting the board. The blade of the saw must be rotating at full speed before it makes contact with the board. If the saw makes contact before it has reach full speed, it may not cut through the material. Worse, it could catch on the cement and potentially break your saw or come loose and injure you.[11]

-

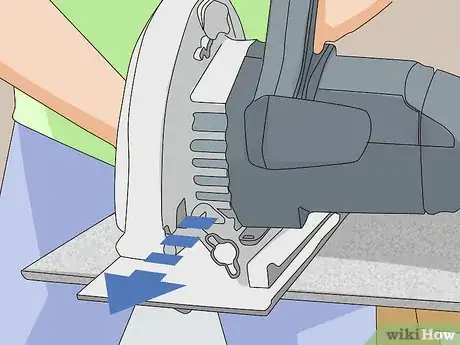

6Push the saw slowly and smoothly through the cement board. With control, guide the blade of the saw through the line you marked on the board. If you push too hard, the blade of the saw could jam in the cement. Listen for the sound of the blade moving through the cement, if it sounds like it is catching and isn’t moving through the material, pause and slow down your advance.[12]

- If the blade does jam, back off slightly and let the blade get back up to speed before moving through the cement again.

- When you saw through the board, make sure that the two halves are secure on the sawhorse so they don’t fall the ground when you cut through it.

Using a Jigsaw to Cut Circular or Irregular Shapes

-

1Use a jigsaw to make rounded cuts in the cement board. Also called a power scroll saw, a jigsaw slightly resembles a bandsaw except that it shorter and cuts in an up-and-down motion. A jigsaw can cut straight cuts, rounded cuts, and is the best choice if you need to cut a circular piece or an irregular shape out of the cement board.[13]

-

2Fit the jigsaw with a metal-cutting blade or a carbide-grit blade. Cement is a tough material to use a jigsaw to cut through, so you need to use the right blade for the job. Use a metal-cutting blade or a carbide-grit blade to cut through the board. Make sure the blade is securely fixed into the saw.[14]

Tip: You may need to replace the blade before you finish cutting through the board, so have a few extra ones on hand.

-

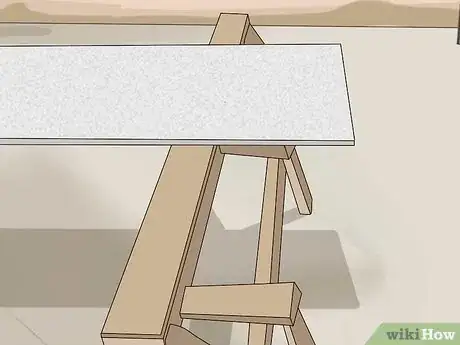

3Place the board on a sawhorse with the top face-up. Lay the board face-up so you can mark the surface and can see the good side of the board as you make cuts. This can help you avoid chipping and cracking when you’re cutting a rounded or irregular shape. Check to make sure the board is secure and stable on the sawhorse.[15]

- A sawhorse is a great tool to help you lay the board flat and keep it secure when you’re sawing, but you can also use a workstation that allows you to cut through the board.

-

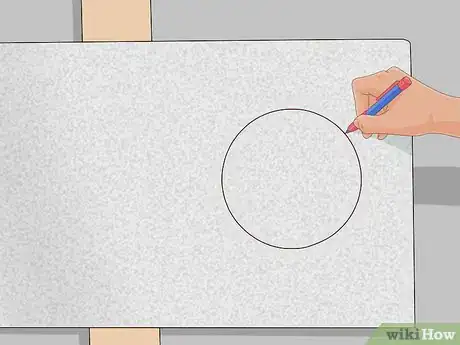

4Mark the board with a pencil to guide the jigsaw. It’s very important to have a guide to follow when you’re using a jigsaw, especially if the shape you are cutting is round or irregular. The advantage of using a jigsaw is that it allows for more a more customizable cut. But that also means that you have to have a good marking of where you plan to saw. Use a carpenter’s pencil to mark on the cement board.

- If you’re cutting a round or irregular shape, you can use a stencil or a round object to help mark an even line.

-

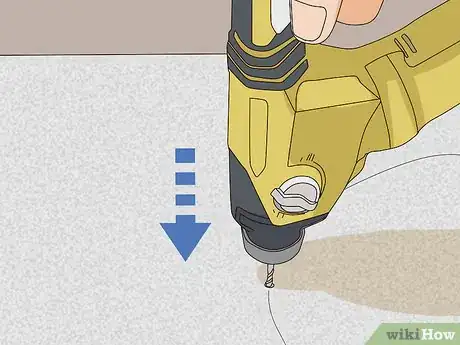

5Drill a hole to fit the jigsaw into the board and at the tightest corners. The jigsaw will need an opening to fit into the cement board, so start by drilling a hole with a drill and masonry bit. If you plan to cut shape with twists and turns, drill holes through the board at the tightest corners of the shape. This will help the jigsaw blade turn when it gets to those turns.[16]

- If the blade of the jigsaw isn’t able to take the turns easily, it could bend the blade or break it.

-

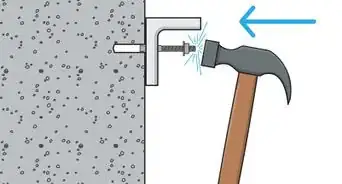

6Insert the saw blade into the hole and bring the blade to full speed. Fit the blade of the jigsaw into the hole you made in the cement board and turn it on. A jigsaw blade moves slower than a band saw or a circular saw, so it must be brought to full speed before you start using it to cut the cement board. If the blade isn’t at full speed when it makes contact with the cement, it could catch and bend or possible break and damage your jigsaw.[17]

- It’s possible the blade cold snap and shoot off the jigsaw and injure you, so use caution.

-

7Push the jigsaw slowly to cut through the board. Apply pressure to keep the jigsaw from jumping off of the board. Follow your guide markings closely and slow down to take any turns. If you hear or feel the blade catching or stalling in the cement board, slow down and back up to allow the blade to get back up to speed, then continue to push the saw through the board.[18]

- Be sure to wear safety glasses and a face mask because the saw will create cement dust.

Warnings

- Sawing cement board can produce concrete dust, which is harmful if inhaled or if it gets into your eyes. Always wear eye protection and breathing protection when sawing cement.⧼thumbs_response⧽

Things You’ll Need

- Ruler or straight edge

- Carpenter’s pencil

- Safety glasses

- Breathing mask or face mask

- Sawhorse or work station

- Utility knife

References

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/

- ↑ https://www.bobvila.com/articles/how-to-cut-cement-board/

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/

- ↑ https://www.bobvila.com/articles/how-to-cut-cement-board/

- ↑ https://www.bobvila.com/articles/how-to-cut-cement-board/

- ↑ Gerber Ortiz-Vega. Masonry Specialist & Founder, GO Masonry LLC. Expert Interview. 10 March 2020.

- ↑ https://www.bobvila.com/articles/how-to-cut-cement-board/

- ↑ https://www.familyhandyman.com/tools/circular-saws/circular-saw-tips-and-techniques/

- ↑ https://www.bobvila.com/articles/975-how-to-cut-straight-lines-with-a-circular-saw/

- ↑ https://www.bobvila.com/articles/975-how-to-cut-straight-lines-with-a-circular-saw/

- ↑ https://www.bobvila.com/articles/975-how-to-cut-straight-lines-with-a-circular-saw/

- ↑ https://www.bobvila.com/articles/2112-jigsaw/

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/

- ↑ https://www.bobvila.com/articles/2112-jigsaw/

- ↑ https://www.bobvila.com/articles/2112-jigsaw/

- ↑ https://www.popularmechanics.com/home/interior-projects/how-to/a8741/how-to-cut-cement-backer-board-for-your-next-tile-job-15238906/