The rate of microbial death can be determined. It is important in order to develop standard protocols for disinfection which will facilitate the sterilization routine in many industries. The goal is to find out what is the minimum time needed to achieve acceptable level of sterilization for a specific purpose. The killing agent can be different (e.g., heat, chemical with certain concentration) depending on the specific application.

When the killing factor is heat, the phrase thermal death can be used. Thermal death time is a concept used to determine how long it takes to kill a specific bacteria at a specific temperature. It was originally developed for food canning and has found applications in cosmetics, and in producing salmonella-free feeds for animals (e.g. poultry, and pharmaceuticals).

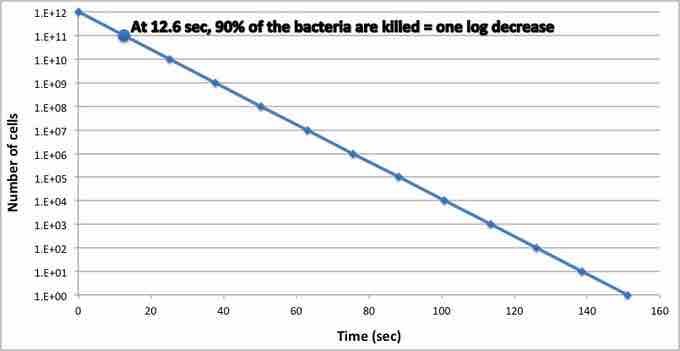

In the food industry, it is important to reduce the amount of microbes in products to ensure proper food safety. This is usually done by thermal processing and finding ways to reduce the number of bacteria in the product. Time-temperature measurements of bacterial reduction is determined by a D-value, meaning how long it would take to reduce the bacterial population by 90% or one log10 at a given temperature. This D-value reference (DR) point is 121°C.

Z or z-value is used to determine the time values with different D-values at different temperatures with its equation shown below:

where T is temperature in °C. Such death curves can be empirically established for all bactericidal agents. This D-value is affected by pH of the product where low pH has faster D values on various foods. The D-value at an unknown temperature can be calculated knowing the D-value at a given temperature provided the Z-value is known. The target of reduction in canning is the 12-D reduction of Clostridium botulinum, which means that processing time will reduce the amount of this bacteria by 1012 bacteria per gram or milliliter. The DR for C. botulinum is 12.6 seconds. A 12-D reduction will take 151 seconds .

Killing curve of C. botulinum

This curve presents the DR value (12.6 seconds) and the 12-D reduction (151 seconds) for C. botulinum. The killing agent is heat at 121ºC.