In the United Kingdom, inventory typically refers to a list compiled for some formal purpose, such as one that itemizes an estate going to probate or the contents of a furnished house to be rented. In the U.S. and Canada, inventory has become the equivalent of the British term stock; that is, it refers to material that is available from and stocked by a business. In the context of accounting, inventory or stock is considered an asset.

Inventory Management

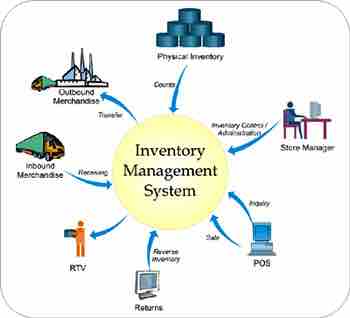

Inventory management tracks the shape and percentage of stocked goods. At different locations within a facility, or within many locations of a supply network, inventory management must precede the regular and planned course of production and stocking of materials .

Inventory Management

Inventory management is primarily concerned with specifying the shape and percentage of stocked goods.

Inventory management addresses a number of concerns, including: replenishment lead time; carrying costs of inventory; asset management; inventory forecasting; inventory valuation; inventory visibility; future inventory price forecasting; physical inventory; available physical space for inventory; quality management; replenishment; returns and defective goods; and demand forecasting. By effectively managing these issues, a business can achieve optimal inventory levels. However, the management process is on-going as a business and its needs shift and respond to the wider environment.

Inventory management often involves a retailer seeking to acquire and maintain a proper merchandise assortment while ordering, shipping, handling, and related costs are kept in check. It requires systems and processes that identify inventory requirements, set targets, provide replenishment techniques, report actual and projected inventory status, and handle all functions related to the tracking and management of material. These include the monitoring of material moved into and out of stockroom locations, as well as the reconciling of inventory balances. Processes may also include ABC analysis, lot tracking, and cycle counting support.

Management of inventories, aimed primarily at determining and controlling stock levels within the physical distribution system, serves to balance the need for product availability against the need for minimizing stock holding and handling costs. Reasons for keeping an inventory include:

- Time: The time lag in the supply chain from supplier to user requires the availability of a certain amount of inventory for use during this lead time. In practice, inventory is maintained for consumption during variations in lead time, and lead time itself can be addressed by ordering a specified number of days in advance.

- Uncertainty: Inventories are maintained as buffers to meet uncertainties in demand, supply, and movement of goods.

- Economies of scale: To deliver one unit of product at a time, and in response to the specific need and location of a given user, would be costly and logistically difficult. In contrast, bulk buying, movement, and storage translate into economies of scale and inventory.

Inventory and the Supply Chain

Supply chain activities can be grouped into strategic, tactical, and operational levels. Inventory considerations present at each level include:

Strategic: Network optimization, including the number, location, and size of warehousing, distribution centers, and facilities.

Tactical: Inventory decisions, including quantity, location, and quality of inventory.

Operational: Sourcing planning, including current inventory and forecast demand, done in collaboration with all suppliers; inbound operations, including transportation from suppliers and receiving inventory; outbound operations, including all fulfillment activities, warehousing, and transportation to customers; management of non-moving, short-dated inventory and avoidance of short-dated products.