Productivity

Productivity–a ratio of production output to the input required to produce it–is one measure of production efficiency. Productivity is defined as a total output per one unit of a total input. Control management must implement control processes to maintain or improve productivity.

Inputs

At the plant level, common input statistics are monetary units, weights or volumes of raw or semi-finished materials, kilowatt hours of power, and worker hours. These are tracked as sets of partial productivity, such as kilowatt-hours per ton or yield (weight of output divided by weight of input), both of which are used in the chemical, refining, wood pulp, and other process industries. Quality statistics like defect rates are tracked in the same way. Summary reports are routinely issued to various departments and department managers are held accountable for managing inputs in their respective areas.

Outputs

Output is simply the rate of which goods are being produced and readied for sale. Managing production levels is part of the control process–management teams must predict demand to avoid market saturation.

From the control manager's point of view, more outputs from the inputs describe above is a step in the right direction. Finding ways to streamline internal operations to minimize cost, limit resource use, and optimize performance (quality) is the control manager's central responsibility. Productivity in producing outputs, in short, can determine a control manager's success or failure.

Productivity and the Firm

Productivity growth is important to a firm because more real income means the firm can meet its obligations to customers, suppliers, workers, shareholders, and governments (taxes and regulation), and still remain competitive or even improve its competitiveness in the marketplace.

Productivity is one of the main concerns of business management and engineering. Practically all companies have established procedures for collecting, analyzing, and reporting productivity data. The accounting department typically has the overall responsibility of collecting, organizing, and storing data generated by various departments.

Improving Productivity

Many companies have formal programs for improving productivity via existing control systems. Companies are constantly looking for ways to improve quality, reduce downtime, and increase inputs of labor, materials, energy, and purchased services. Simple changes to operating methods or processes can increase productivity (think Henry Ford's assembly line). The biggest gains often come from adopting new technologies or concepts, which requires capital expenditures for new equipment, computers, or software.

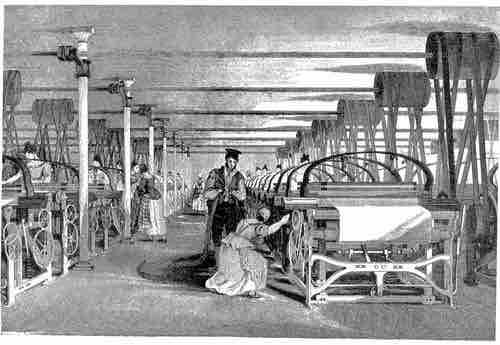

Textile manufacturing

During the Industrial Revolution, productivity increased with the implementation of the assembly line.